Eaton 6A-24-45HB48 Horizontal Bend - UL Classified

Part Number: 6A-24-45HB48

Quick Summary

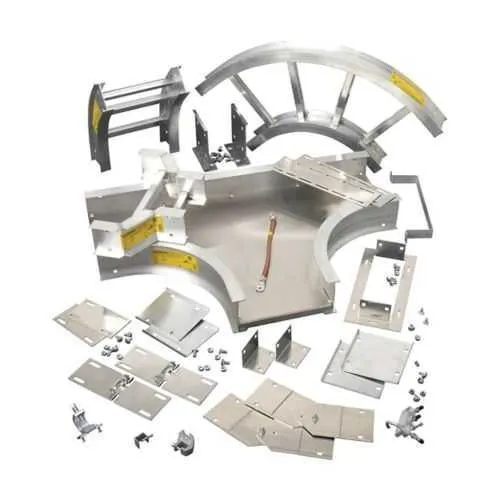

Eaton 6A-24-45HB48 horizontal bend is designed to guide cable trays with precision in industrial environments. Too often projects stall when bends add weight, complicate routing, or require rework. UL Classified, CSA, and CE certifications support compliance across North America and beyond. In practice, this aluminum bend reduces weight, speeds installation, and improves long-term tray performance. With compatible B-Line components and industry-standard radii, it helps engineers meet project timelines and budgets. The result is a robust, install-ready solution for aluminum cable tray turns that minimizes maintenance while maximizing system reliability.

Product Information

Extended Description

6A-24-45HB48 Eaton: Eaton B-Line series horizontal bend, 6" H x 47.5625" W x 24" L, Aluminum, 48" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-45HB48

UPC

781011209513

Product Length/Depth

47.5625 in

Product Height

6 in

Product Width

24 in

Product Weight

14.2 lb

Certifications

UL Classified CSA CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

48 in

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-45HB48

Aluminum construction reduces overall weight, easing crane- or ladder-assisted installation on crowded facilities racks and mezzanines, which translates to lower labor costs and safer handling in busy plants. This lightweight yet durable bend supports efficient installation of aluminum cable tray systems while maintaining rigidity for long runs in harsh environments. Radius and angle are tuned to minimize sharp transitions; the 48 in radius and 45° geometry enable gradual turns that protect cable integrity and reduce bend-induced fatigue. The business impact is lower risk of cable damage and fewer corrective interventions during commissioning, especially in data centers and manufacturing lines needing reliable routing. Dimensions of 6 in height, 24 in width, and a 47.5625 in length offer predictable footprinting and straightforward mounting alongside standard supports. Weighing 14.2 lb, this bend balances strength and manageability for field crews. Certifications UL Classified, CSA, and CE ensure compliance with global standards, simplifying approvals in multinational projects. Series 2-5 compatibility guarantees seamless integration with existing Eaton cable management ecosystems, plus access to DIN rail and rack-fittings where applicable. Installation is aided by documented configurations and compatible fasteners, reducing time-to-first-use. This bend is suitable for NEMA cable management applications, where standardized radii and aluminum construction meet industry-forced margins and service-life expectations. In practice, it supports quick rework or expansion as facility layouts evolve, delivering durable performance with lower total cost of ownership.

Get a Quick Quote for a Eaton 6A-24-45HB48

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-45HB48?

Enquire Now

FAQs

The 6A-24-45HB48 is part of the Eaton B-Line family and is designed for seamless compatibility with existing B-Line components and supports. Its Series 2-5 designation indicates standardized radii, mounting interfaces, and connection methods that align with other bends, tees, and splices. Installation teams benefit from a consistent design language, reducing hardware variation and improving overall project timelines.

Plan for a 45° turn with a 48 in radius to minimize cable bend strain and tray deflection. Ensure sufficient clearance around the 47.5625 in length and 24 in width. Use compatible mounting hardware and follow the documented installation instructions to maintain UL Classified, CSA, and CE compliance. Verify support spacing and loading to prevent tray overspans or misalignment during commissioning.

Yes. The bend is aluminum, offering good corrosion resistance and lighter weight for easy handling in data centers and manufacturing floors. Its UL Classified, CSA, and CE certifications support regulatory compliance in many regions, while the 48 in radius reduces stress on cables in high-density deployments, improving reliability and service life in demanding environments.

The 6A-24-45HB48 carries UL Classified, CSA, and CE certifications. These indicate verified safety, performance, and conformity with both North American and international standards. For buyers, this simplifies regulatory approvals, aids in vendor qualification, and reduces risk during audits or facility inspections, particularly in industries with strict electrical and electrical-support equipment requirements.

The aluminum construction lowers weight and simplifies handling, which reduces labor costs during installation and future reconfigurations. The durable material and standardized radii minimize cable damage and rework, contributing to lower maintenance expenses. Over time, the compatibility with Series 2-5 components helps preserve the value of existing cable management investments by enabling scalable upgrades without replacing entire runs.