Eaton 6A-24-60HB24 Cable Tray Horizontal Bend - CSA UL CE

Part Number: 6A-24-60HB24

Quick Summary

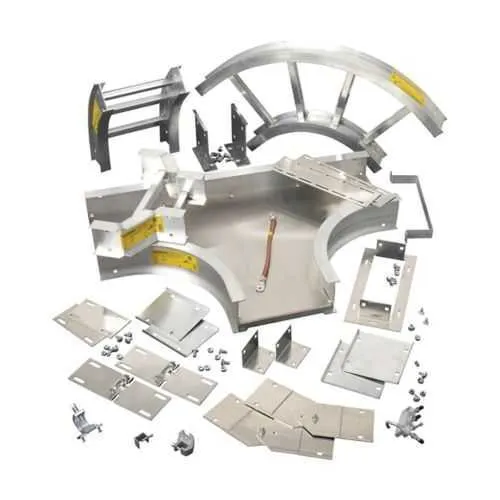

The Eaton B-Line series horizontal bend, 6A-24-60HB24, provides curved routing for aluminum cable tray runs in industrial electrical installations. When space is tight or fittings are mismatched, installation can stall and budgets can drift. This component carries CSA, UL Classified, and CE certifications, validating performance and safety in harsh industrial environments. By aligning with standard 24 in radius trays and 60° routing, it supports scalable wiring layouts while reducing field corrections and downtime. Engineered for compatibility with Eaton B-Line cable tray systems and aluminum fittings, it helps engineers meet project timelines and regulatory requirements.

Product Information

Extended Description

6A-24-60HB24 Eaton: Eaton B-Line series horizontal bend, 6" H x 35.75" W x 24" L, Aluminum, 24" radius, 60° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-60HB24

UPC

781011209490

Product Length/Depth

35.75 in

Product Height

6 in

Product Width

24 in

Product Weight

12.1 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

60°

Radius

24 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-60HB24

Feature → Business Impact → Application: The 6A-24-60HB24 uses a 60° bend with a 24 in radius, enabling smooth curvature in long cable tray runs. This reduces the number of fittings required, cutting material cost and field labor while improving routing integrity in data centers and manufacturing floors. Application: Ideal for 60° turns in aluminum cable tray systems, compatible with KwikSplice fittings and Redi-Rail installations to accelerate setup and maintenance. Feature → Business Impact → Application: Aluminum construction delivers corrosion resistance and weight savings, easing handling and improving lifecycle value. Application: Suitable for harsh industrial environments where CSA UL CE compliance is essential. Feature → Business Impact → Application: 35.75 in length and 24 in width with a 6 in height ensures predictable space planning, enabling modular layouts and faster project completion. Feature → Business Impact → Application: Documentation and manuals (Cable Tray Manual and installation sheets) streamline on-site assembly, reducing rework and compliance risk.

Get a Quick Quote for a Eaton 6A-24-60HB24

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-60HB24?

Enquire Now

FAQs

The 6A-24-60HB24 is designed for seamless integration with Eaton B-Line aluminum cable trays and compatible fittings, including KwikSplice and Redi-Rail universal fittings. Its precise 60° angle and 24 in radius preserve routing continuity, reduce the number of intermediary parts, and accelerate on-site assembly without sacrificing electrical performance or labor efficiency.

Key specs include a 60° bend with a 24 in radius, aluminum material, 35.75 in length, 6 in height, and 24 in width, with a weight of 12.1 lb. These dimensions support consistent layout planning, predictable clearance, and straightforward mounting in standard cable tray runs, minimizing rework and ensuring fit within equipment racks and ceiling paths.

Industries such as data centers, manufacturing facilities, and process automation plants benefit most, as the curvature enables tight routing around equipment and column spacing while maintaining organized cable management. The aluminum construction helps with weight considerations during installation and long-term corrosion resistance in demanding environments.

The bend carries CSA, UL Classified, and CE certifications, signaling compliance with North American and European safety and performance standards. For engineers, these certifications reduce regulatory risk, simplify procurement for regulated projects, and support warranty and maintenance planning across multiple sites.

Using the 6A-24-60HB24 can shorten installation time by reducing the number of fittings and simplifying routing, lowering labor costs and project schedules. Its aluminum construction provides corrosion resistance, potentially extending lifecycle in harsh environments and reducing maintenance intervals, contributing to a lower total cost of ownership.