Eaton 6A-24-90HB36 Horizontal Bend - CSA UL Classified

Part Number: 6A-24-90HB36

Quick Summary

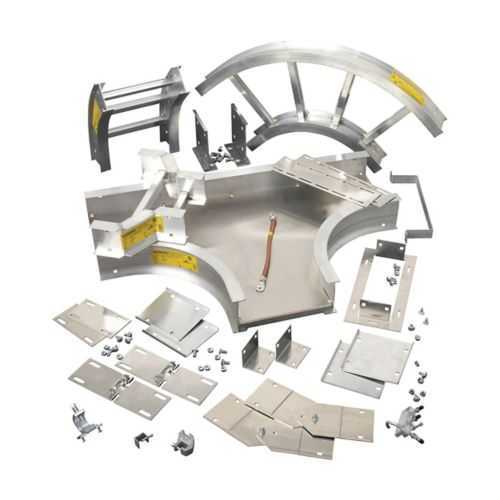

Eaton 6A-24-90HB36 horizontal bend enables clean 90-degree turns in B-Line cable tray systems for industrial facilities. In dense layouts, misaligned bends, excess weight, and corrosion risk slow installation and inflate costs. This bend meets CSA, CE, and UL Classified standards, ensuring regulatory compliance and safety across global builds. For project teams, the aluminum construction and precise 36 in radius deliver long-term durability and easier, faster installation with compatible Eaton cable tray fittings and accessories, enabling efficient vertical and horizontal routing in electrical installations.

Product Information

Extended Description

6A-24-90HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 51.0625" W x 24" L, Aluminum, 36" radius, 90° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-24-90HB36

UPC

781011209551

Product Length/Depth

51.0625 in

Product Height

6 in

Product Width

24 in

Product Weight

25.6 lb

Certifications

CSA CE UL Classified

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

90°

Radius

36 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-24-90HB36

The aluminum construction of the 6A-24-90HB36 provides a robust, corrosion-resistant component that supports long service life in demanding industrial environments, reducing maintenance intervals and total cost of ownership. Feature → Business Impact → Application: Aluminum material delivers weight reduction and improved heat dissipation, which translates to easier handling during installation and better performance in high-density cable runs, particularly in automation cells and control rooms. Application: Use in B-Line cable tray systems to achieve precise 36 in radius, 90-degree routing for clean workflow layouts, improving airflow and cable organization in data centers and manufacturing floors. Certifications such as CSA, CE, and UL Classified underpin compliance with global electrical standards, mitigating project risks and expediting approvals. Application: Suitable for industrial automation installations where regulatory adherence and documented performance are non-negotiable. The 51.0625 in length and 6 in by 24 in footprint enable predictable fit along rack rails and equipment housings, reducing field trimming and alignment issues, which translates to faster installs and fewer change orders. Industry context: Contractors and integrators benefit from standardized fittings that reduce installation time and training needs, aligning with lean manufacturing and project throughput goals.

Get a Quick Quote for a Eaton 6A-24-90HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-24-90HB36?

Enquire Now

FAQs

The 6A-24-90HB36 is manufactured as a B-Line series horizontal bend and is designed for seamless integration with Eaton B-Line aluminum cable tray components. Its 51.0625 in length and 36 in radius ensure consistent spacing and alignment with standard fittings, simplifying site assembly and minimizing field modifications.

Key specs include product name Eaton B-Line series horizontal bend, catalog number 6A-24-90HB36, aluminum material, 90° angle, 36 in radius, 51.0625 in length, 6 in height, 24 in width, and a weight of 25.6 lb. Certifications listed are CSA, CE, and UL Classified.

The provided data specifies aluminum construction and regulatory certifications (CSA, CE, UL Classified), which support indoor electrical installations within standard facilities. For outdoor or harsh environments, verify environmental ratings, coatings, and IP/Ingress protection with the manufacturer or a qualified integrator.

The bend carries CSA, CE, and UL Classified certifications. These attest to electrical safety, performance under compliance standards, and global market readiness, reducing project risk, easing code approvals, and facilitating cross-border specifications in multi-site deployments.

With precise fabrication and a standardized footprint, the 6A-24-90HB36 minimizes field adjustments, speeds integration with Eaton B-Line trays, and improves cable organization. The result is shorter installation cycles, lower labor costs, and predictable long-term performance in automation and manufacturing environments.