Eaton 6A-30-60HB24 Horizontal Bend - UL Classified

Part Number: 6A-30-60HB24

Quick Summary

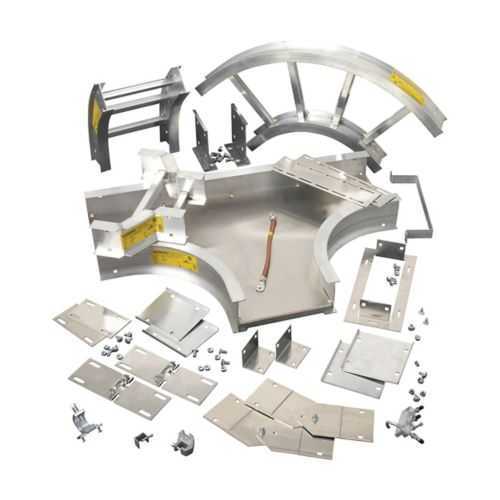

Eaton B-Line series horizontal bend enables efficient cable tray routing for industrial facilities. Installers often contend with tight radii, misaligned hardware, and lengthy fitting lists that slow project timelines. This bend carries UL Classified, CSA, and CE certifications to support safe, regulated installations. Its aluminum construction, 24 in radius, and 60° bend provide durable, scalable solutions for data centers, manufacturing floors, and other wiring-intensive environments. Together with its precise dimensions and compatibility with Eaton's Series 1 to 5 catalog, it helps reduce installation time and ongoing maintenance costs while supporting dependable, compliant cable management.

Product Information

Extended Description

6A-30-60HB24 Eaton: Eaton B-Line series horizontal bend, 6" H x 38.3125" W x 30" L, Aluminum, 24" radius, 60° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-30-60HB24

UPC

781011210373

Product Length/Depth

38.3125 in

Product Height

6 in

Product Width

30 in

Product Weight

14.7 lb

Certifications

UL Classified CSA CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

60°

Radius

24 in

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-30-60HB24

Feature → Business Impact → Application: Aluminum construction delivers corrosion resistance and light in-weight handling, enabling simpler hoisting and faster on-site assembly in rugged industrial settings. This reduces labor costs and enables safer, maintenance-friendly installations for long-running production lines. Feature → Business Impact → Application: A precise 24 inch radius and 60° bend design minimizes misrouting and misalignment, improving cable tray performance and limiting stress on cables in critical data centers and manufacturing floors. Feature → Business Impact → Application: Large 38.3125 inch length and 30 inch width provide ample clearance for multi-cable runs, simplifying crew coordination and reducing rework during system expansion. Feature → Business Impact → Application: UL Classified, CSA, and CE certifications support regulatory compliance and traceable quality, easing procurement processes for contractors and engineers. Feature → Business Impact → Application: Compatibility with Eaton KwikSplice and Redi-Rail fittings and the Series 1–5 catalog enhances install versatility and stock efficiency, cutting project lead times. Feature → Business Impact → Application: The 14.7 lb weight balances strength with handling ease, lowering fatigue and improving safety during field assembly in crowded cable trays. This combination of material, geometry, and certification delivers measurable ROI through faster installs, fewer components, and robust, compliant cable management.

Get a Quick Quote for a Eaton 6A-30-60HB24

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-30-60HB24?

Enquire Now

FAQs

Yes. The 6A-30-60HB24 is designed for Eaton B-Line Series cable tray systems and is compatible with Series 2–5 horizontal bend configurations. It aligns with KwikSplice cable tray systems and Redi-Rail fittings, simplifying field assembly and allowing fast, tool-light installation on aluminum trays. Its 38.3125 inch length and 6 inch height accommodate common rack layouts while preserving clearances for cable bundles.

Key specs include material: aluminum; radius: 24 inches; angle: 60 degrees; dimensions: approximately 38.3125 inches in length, 6 inches in height, and 30 inches in width; catalog number: 6A-30-60HB24; weight: 14.7 pounds; certifications: UL Classified, CSA, CE; UPC: 781011210373.

Yes. This bend carries UL Classified, CSA, and CE certifications, which support compliance and safety in standard indoor industrial applications. It is designed for aluminum cable management in commercial and manufacturing environments, ensuring consistent performance under typical service conditions and aiding procurement with recognized certifications.

The 24 in radius minimizes bending stress on cables and reduces sag over long runs, while the 60° angle provides a precise corner transition that fits common floor plans and rack layouts. Together they enable predictable routing, reduce rework, and improve airflow and cable organization in busy facilities.

The combination of lightweight aluminum construction, certified compliance, and standardized geometry lowers labor time and reduces part variety. Installations are faster, fewer field adjustments are required, and maintenance costs are minimized due to durable, corrosion-resistant materials and a repeatable, scalable bend that supports future expansion.