Eaton 6A-36-45HB12 B-Line Horizontal Bend - CE UL CSA

Part Number: 6A-36-45HB12

Quick Summary

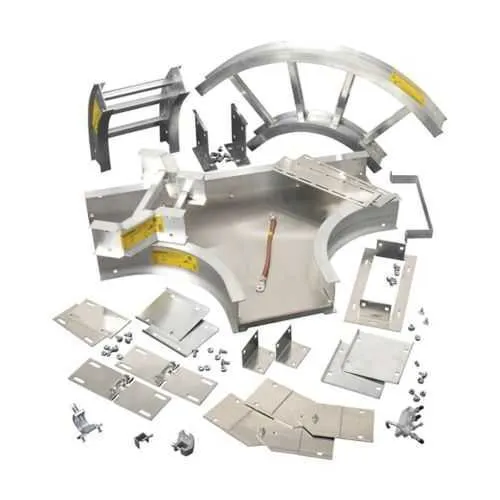

Eaton B-Line horizontal bend is a cable-tray component used to route runs around corners in industrial electrical installations. When space is tight or layouts demand precise geometry, installers often struggle with misaligned bends, cable damage, and time-wasting adjustments. This model meets CE, UL Classified, and CSA certifications, reinforcing safety, compliance, and traceability in critical environments. Made from aluminum for rugged yet lightweight performance, it features a 12 in radius and a 45° angle to fit standard tray systems without reshaping. Designed for seamless compatibility with Eaton B-Line products and compatible aluminum cable-tray components, it delivers faster installs, lower labor costs, and reliable long-term operation.

Product Information

Extended Description

6A-36-45HB12 Eaton: Eaton B-Line series horizontal bend, 6" H x 26.3750" W x 36" L, Aluminum, 12" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-36-45HB12

UPC

781011211462

Product Length/Depth

26.375 in

Product Height

6 in

Product Width

36 in

Product Weight

12 lb

Certifications

CE UL Classified CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

12 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-36-45HB12

Feature: Aluminum construction provides corrosion resistance and rugged durability while keeping weight manageable. Business Impact: Reduces handling effort, freight costs, and wear on supporting structures during installation and service. Application: Ideal for overhead and wall-mounted cable tray runs in industrial facilities, data centers, and process plants where long service life matters. Feature: A 12 in radius and a 45° bend geometry deliver smoother cable paths and lower bend-induced stress. Business Impact: Improves conductor life, reduces risk of insulation damage, and speeds up field routing. Application: Aligns with standard Eaton B-Line aluminum cable trays and KwikSplice/Redi-Rail fittings for quick, reliable assembly in constrained spaces. Feature: Overall clearances and dimensions—6 in height, 36 in width, 26.375 in length—with an approximate 12 lb weight. Business Impact: Predictable footprint simplifies layout planning, reduces rework, and enables straightforward securing with common hardware. Application: Supports modular tray systems in 36 in wide configurations and integrates with existing cable-management hardware. Feature: Certifications CE, UL Classified, CSA. Business Impact: Regulatory alignment reduces risk during audits, procurement, and installation acceptance. Application: Suitable for safety-critical industrial environments, data centers, and control rooms that demand certified cable-management components. Feature: Availability of manuals, datasheets, and installation guides. Business Impact: Improves installer onboarding, ensures correct use, and speeds up commissioning. Application: Use the Eaton catalog PDFs and KwikSplice/Redi-Rail instructions for best results.

Get a Quick Quote for a Eaton 6A-36-45HB12

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-36-45HB12?

Enquire Now

FAQs

To install the 6A-36-45HB12 horizontal bend, align it with Eaton B-Line aluminum cable-tray sections and secure it with compatible fasteners per the KwikSplice/Redi-Rail installation guidelines. The unit features a 12 in radius and a 45° bend to maintain cable integrity. It integrates with standard 36 in wide trays and UL CE CSA compliant equipment, streamlining field assembly.

Key specifications include aluminum construction, 12 in radius, 45° angle, 6 in height, 36 in width, and 26.375 in length, with a nominal 12 lb weight. Catalog number 6A-36-45HB12, it carries CE, UL Classified, and CSA certifications and is designed for Eaton B-Line cable trays. The combination supports smooth, compliant cable routing in demanding industrial environments.

Yes. The 6A-36-45HB12 is suitable for data centers and industrial floors requiring reliable cable routing. Its aluminum construction resists corrosion, making it appropriate for controlled environments, while the 12 in radius and 45° bend help maintain cable integrity over long runs. Certifications (CE, UL Classified, CSA) support compliance in mission-critical applications.

The bend carries CE, UL Classified, and CSA certifications, signaling compliance with European, U.S., and Canadian safety standards. These marks aid in site acceptance, audits, and procurement decisions, reducing risk in safety-critical installations. The certified bend also ensures compatibility with Eaton B-Line systems and common fittings like KwikSplice and Redi-Rail.

The Eaton bend can lower total cost of ownership through faster installs, lighter handling (12 lb), and compatibility with KwikSplice/Redi-Rail systems, reducing labor and inventory complexity. Its corrosion-resistant aluminum construction extends service life, minimizing maintenance intervals and downtime in demanding manufacturing or data-center environments.