Eaton 6A-36-90HB36 Horizontal Bend - CSA UL Classified CE

Part Number: 6A-36-90HB36

Quick Summary

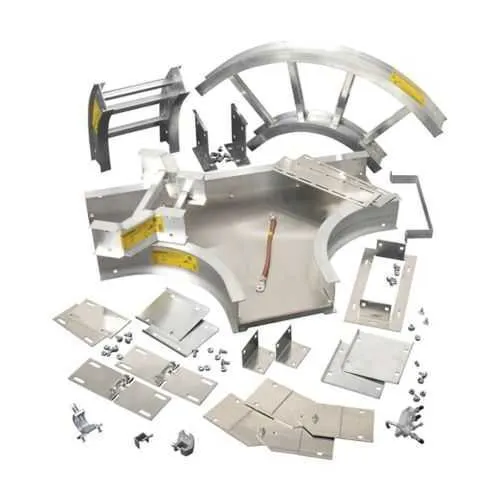

The Eaton 6A-36-90HB36 horizontal bend enables safe, organized cable tray routing in industrial enclosures. In busy facilities, awkward corners and misaligned trays slow maintenance and elevate the risk of cable damage. Certified CSA, UL Classified, and CE marked for global compliance, this bend supports demanding electrical installations. Designed for aluminum B-Line systems, its 36-inch radius and 90° angle help reduce installation time and improve long-term system reliability, making it a practical choice for scalable, compliant cable management in manufacturing, data centers, and controlled environments.

Product Information

Extended Description

6A-36-90HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 57.0625" W x 36" L, Aluminum, 36" radius, 90° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-36-90HB36

UPC

781011211585

Product Length/Depth

57.0625 in

Product Height

6 in

Product Width

36 in

Product Weight

34.7 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

90°

Radius

36 in

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

Series 1 to 5 Section of NEMA Cable Management Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-36-90HB36

Aluminum construction delivers corrosion resistance and a lighter weight compared to steel equivalents, improving handling during installation and reducing personnel strain on tight access runs. This translates to lower maintenance costs and longer service life in rugged industrial environments, particularly where vibration or humidity is a concern. The 36-inch radius provides a generous bend, reducing stress on cables and improving airflow around the tray, which can lower heat buildup and extend component life in high-density installations. A true 90° angle supports predictable routing around equipment, minimizing space requirements and enabling faster layout planning for electrical rooms and process lines. With a footprint of 57.0625 inches in length, 6 inches in height, and 36 inches in width (weight 34.7 pounds), installers gain precise, repeatable fitment for modular layouts. Certifications CSA, UL Classified, and CE ensure compliance across regional specs, easing cross-border procurement and reducing product qualification time. Compatibility with Series 2-5 horizontal bends and related KwikSplice/Redi-Rail fittings enhances installation efficiency and provides a cohesive, scalable cable management solution across diverse facilities.

Get a Quick Quote for a Eaton 6A-36-90HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-36-90HB36?

Enquire Now

FAQs

Plan for mounting to standard aluminum cable trays compatible with Eaton B-Line Series 2-5 bends. Allow unobstructed access for assembly, use compatible hardware, and follow the KwikSplice/Redi-Rail guidance when integrating with fittings. Verify tray width and reach to ensure the 57.0625 inch length fits the intended run without stressing cables.

A larger 36 in radius minimizes acute bends, reducing bend radius violations and cable compression. This improves flexibility for high-density cables and minimizes heat buildup, enabling smoother long-span routing in equipment rooms and process lines while preserving tray clearances and simplifying future upgrades.

Yes. The bend is CSA listed, UL Classified, and CE marked, signaling compliance with applicable safety and performance requirements. This enables easier acceptance in regulated installations, supports quality assurance during audits, and helps meet international procurement criteria for multi-site projects.

Ideal for aluminum B-Line cable tray systems in electrical rooms, data centers, and manufacturing floors. Its 90° configuration supports corner transitions around equipment, while the 36 in radius accommodates long, gentle curves ideal for large-diameter or multiple cable runs, reducing maintenance complexity and improving serviceability in automated facilities.

The aluminum construction lowers weight, easing handling and reducing labor time during installation. The generous radius reduces cable stress and potential future rework, while global certifications streamline compliance checks. Together, these factors shorten project timelines, reduce downtime, and improve ongoing reliability in critical electrical and automation infrastructure.