Eaton 6A-42-45HB12 Horizontal Bend - UL Classified CE CSA

Part Number: 6A-42-45HB12

Quick Summary

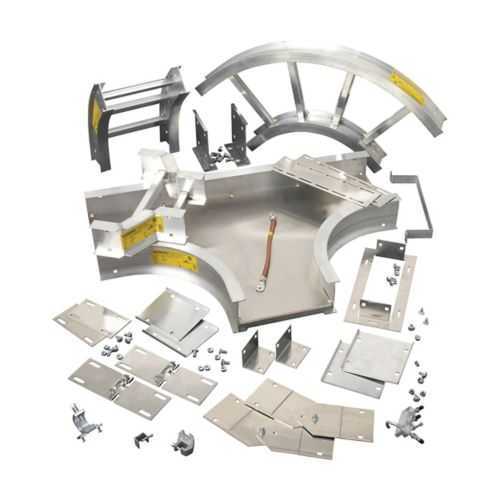

Eaton 6A-42-45HB12 Horizontal Bend enables clean cable-tray routing around 45-degree corners in industrial enclosures. It helps avoid misaligned bends that cause installation delays and increased labor costs. UL Classified, CE, and CSA certifications support safety and compliance across global sites, making it suitable for international projects. Built for aluminum cable trays in Eaton’s B-Line series, it delivers lightweight handling and straightforward installation, shrinking project timelines. Designed for standardized components, it reduces on-site errors and maintenance needs, improving long-term reliability of power and data pathways while preserving airflow and cable integrity.

Product Information

Extended Description

6A-42-45HB12 Eaton: Eaton B-Line series horizontal bend, 6" H x 47.37" W x 42" L, Aluminum, 12" radius, 45° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-42-45HB12

UPC

781011212438

Product Length/Depth

47.37 in

Product Height

6 in

Product Width

42 in

Product Weight

14.6 lb

Certifications

UL Classified CE CSA

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

45°

Radius

12 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-42-45HB12

Feature: Aluminum construction and 6 in height provide a rugged yet lightweight bend that resists corrosion in factory environments. Business impact: reduces handling effort on site and lowers replacement costs over the life of the system. Application: ideal for long runs in manufacturing plants using Eaton B-Line cable-tray systems, where weight savings speed up installation without sacrificing strength. Feature: 47.37 in length and 42 in width define a wide, compatibility-forward geometry that aligns with standard trays, reducing rework and ensuring a seamless fit in existing racks. Business impact: minimizes field adjustments and accelerates commissioning in automation facilities. Application: suitable for continuous runs along equipment lines in process facilities. Feature: 12 in radius and 45° angle deliver smooth transitions that protect conductors, maintain airflow, and simplify routing. Business impact: lowers cable fatigue risk and simplifies future upgrades. Application: ideal for machine cells and assembly lines in manufacturing environments. Feature: Certifications UL Classified, CE, CSA provide multi-market compliance and safety assurance. Business impact: reduces procurement risk and ensures regulatory alignment across sites. Application: supports global installations in hospitals, data centers, and factories. Feature: Compatibility with Eaton B-Line aluminum cable-tray systems and available installation resources such as manuals and datasheets. Business impact: speeds retrofits and standardizes hardware across projects. Application: fits KwikSplice systems and OEM installations, enabling faster splices and mounting.

Get a Quick Quote for a Eaton 6A-42-45HB12

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-42-45HB12?

Enquire Now

FAQs

To install the 6A-42-45HB12, verify compatibility with Eaton B-Line aluminum cable-tray systems and ensure the bend orientation follows the intended cable path. The unit weighs 14.6 lb, so plan for safe handling during mounting and alignment. Use standard hardware and reference the Eaton datasheet for recommended mounting clearances and support spacings to achieve a secure, code-compliant bend.

Key specs include an aluminum construction with dimensions of 6 in height, 42 in width, and 47.37 in length, a 12 in radius, and a 45° bend angle. Catalog number is 6A-42-45HB12, UPC 781011212438, and it is UL Classified, CE, CSA certified, designed for Eaton B-Line cable-tray systems.

Yes. The 6A-42-45HB12 carries UL Classified, CE, and CSA certifications, ensuring safety and regulatory compliance across multiple markets. This makes it appropriate for global installations in manufacturing facilities, data centers, and process plants where standardized cable-routing components are required.

Applications include industrial automation environments, machine-building cells, and data-center cabling where 45-degree routing minimizes space constraints while preserving airflow. The aluminum construction keeps weight manageable for quick installs, and the bend integrates with Eaton’s B-Line system to streamline layouts, spares, and future expansions.

The bend reduces installation time and field adjustments due to its standardized geometry and compatibility with B-Line trays, contributing to lower labor costs. Its aluminum body offers durability with corrosion resistance, lowering replacement needs over time. Certifications and documentation support faster procurement and regulatory confidence, improving project ROI in mid to large-scale installations.