Eaton 6A-42-90HB36 B-Line horizontal bend - CSA UL CE

Part Number: 6A-42-90HB36

Quick Summary

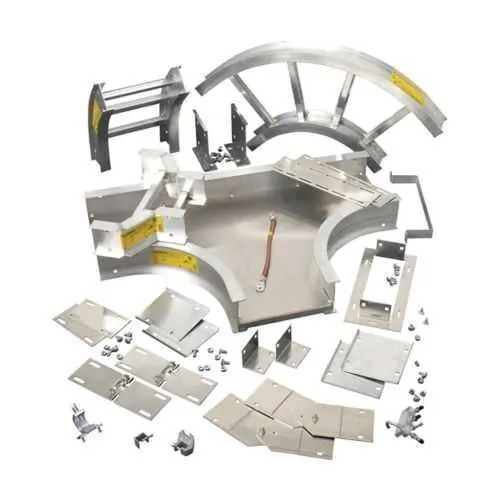

Eaton B-Line horizontal bend is a durable aluminum elbow used to route cable trays through equipment enclosures. Engineers and installers often grapple with sharp turns that slow progress and risk cable damage in tight spaces. Certifications like CSA, UL Classified, and CE signal robust compliance for electrical safety and installation integrity. With a 36 in radius, aluminum construction, and a 90° angle, this bend supports lightweight, scalable runs in data centers, industrial facilities, and control rooms. By pairing this bend with compatible trays and fittings, projects gain faster installation, lower maintenance costs, and improved airflow management across the system.

Product Information

Extended Description

6A-42-90HB36 Eaton: Eaton B-Line series horizontal bend, 6" H x 115.05" W x 42" L, Aluminum, 36" radius, 90° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-42-90HB36

UPC

781011212568

Product Length/Depth

115.05 in

Product Height

6 in

Product Width

42 in

Product Weight

39.5 lb

Certifications

CSA UL Classified CE

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

90°

Radius

36 in

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

Cable tray and Cable Management NEMA Catalog

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-42-90HB36

Feature: Aluminum construction provides corrosion resistance while maintaining a lightweight profile. Business Impact: Easier handling during installation reduces labor time and fatigue on site. Application: Ideal for overhead or rack-mounted cable runs in data centers and industrial facilities. Feature: 90° bend with a 36 in radius delivers a smooth, gradual turn. Business Impact: Minimizes cable bending stress, improves airflow, and lowers the risk of damage during thermal cycling. Application: Critical for high-density cable layouts and long routing runs. Feature: Large footprint with 115.05 in length and 42 in width supports continuous runs with fewer joints. Business Impact: Reduces wait time for additional fittings, lowers inventory complexity, and accelerates project timelines. Application: Suitable for extended cable tray segments in control rooms and plant floors. Feature: Certifications CSA, UL Classified, CE provide compliance assurances. Business Impact: Simplifies procurement, enhances QA during audits, and supports regulated environments. Application: Required in many regional electrical installations and data-center projects. Feature: Compatibility with Eaton KwikSplice and Redi-Rail fittings (CTIS-20) streamlines sourcing and installation. Business Impact: Cuts strikes of rework, lowers field labor, and supports rapid commissioning. Application: Works across Eaton cataloged cable-management ecosystems and modular installations.

Get a Quick Quote for a Eaton 6A-42-90HB36

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-42-90HB36?

Enquire Now

FAQs

The 6A-42-90HB36 is designed for Eaton B-Line series cable tray systems and fits standard aluminum and steel trays used in commercial and industrial installations. It supports the KwikSplice and Redi-Rail Universal fitting ecosystem and aligns with Eaton catalogs for quick integration. Compatibility extends to long runs approximating the Bend's 115.05 in length with the 36 in radius geometry.

A 36 in radius provides a broad, gradual curve that reduces sharp knee bends, helping to prevent cable kinking and ensuring better airflow in densely populated racks. This reduces cable wear during thermal cycling and supports reliable, high-density cabling layouts typical of data centers and telecom rooms.

The bend carries CSA, UL Classified, and CE certifications, which satisfy many regional electrical and safety requirements. These approvals help streamline procurement and QA during audits, but site-specific codes and project specifications should still be consulted to confirm compliance for a given installation.

Lightweight aluminum construction lowers handling time and simplifies rigging compared with heavier metals. The 90°/36 in geometry minimizes the number of fittings, and Eaton's catalogs and installation instructions (CTIS-20) streamline sourcing and on-site assembly, reducing labor, downtime, and total project costs.

By shortening installation time, improving cable management, and reducing misrouted cables and sharp bends, the 6A-42-90HB36 can shorten project schedules and extend system life. Certifications and compatibility with standard fittings also lessen rework, warranty risk, and ongoing maintenance costs over the life of the installation.