Eaton 6A-42-90HB48 horizontal bend - UL Classified

Part Number: 6A-42-90HB48

Quick Summary

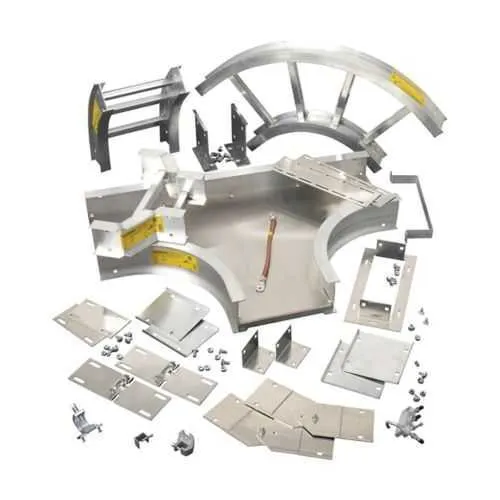

Eaton 6A-42-90HB48 horizontal bend is a 90-degree aluminum transition for B-Line cable tray systems in industrial facilities. It helps you maintain clean, continuous cable routing in tight spaces where sharp corners are impractical. The design supports CE, CSA, and UL Classified certifications, underscoring compliance across international sites. This combination of durable aluminum construction, a generous 48 in radius, and a 132.02 in length reduces rework, accelerates installation, and improves airflow in trays. By pairing with Eaton accessories, you can standardize bends across facilities, improve vendor consolidation, and lower lifecycle costs while meeting rigorous industry standards.

Product Information

Extended Description

6A-42-90HB48 Eaton: Eaton B-Line series horizontal bend, 6" H x 132.02" W x 42" L, Aluminum, 48" radius, 90° angle

Product Name

Eaton B-Line series horizontal bend

Catalog Number

6A-42-90HB48

UPC

781011212582

Product Length/Depth

132.02 in

Product Height

6 in

Product Width

42 in

Product Weight

39.6 lb

Certifications

CE CSA UL Classified

Material

Aluminum

Type

Series 2-5 horizontal bend

Angle

90°

Radius

48 in

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

Cable Tray Manual - 2014 Version

KwikSplice Cable Tray System and Redi-Rail Series Universal Fitting Assembly

Eaton Specification Sheet - 6A-42-90HB48

Feature: Aluminum construction provides corrosion resistance and long life in tough environments. Business Impact: Reduces maintenance costs and unplanned downtime by delivering a rugged bend that withstands humidity, dust, and temperature swings. Application: Ideal for Eaton B-Line aluminum cable tray systems in Series 2-5 installations where dependable bends are essential for continuous routing. Feature: 90-degree bend with a 48 in radius enables smooth, wave-free cable routing. Business Impact: Minimizes bending stress on cables and lowers insulation wear and future rework. Application: Suitable for long tray runs in data centers and manufacturing lines that use the 132.02 in length and 48 in radius design. Feature: CE, CSA, UL Classified certifications ensure regulatory compliance. Business Impact: Simplifies audits and reduces risk of non-compliance across global sites. Application: Supports installation in facilities requiring standardized cable tray components. Feature: Large length and width (132.02 in x 42 in) with 6 in height offers ample clearance for cables and accessories. Business Impact: Improves cable management flexibility and reduces field fabrication. Application: Works with standard mounting patterns in Eaton B-Line trays and compatible fittings. Feature: Weight 39.6 lb balances rigidity with manageable handling during installation. Business Impact: Enables secure, straightforward mounting with common hardware, cutting setup time. Application: Ideal for large-scale tray runs and retrofit projects in industrial environments.

Get a Quick Quote for a Eaton 6A-42-90HB48

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton 6A-42-90HB48?

Enquire Now

FAQs

The 6A-42-90HB48 is designed for seamless integration with Eaton B-Line aluminum cable tray systems, specifically supporting Series 2-5 horizontal bends. Its 132.02 in length, 42 in width, 6 in height, and 48 in radius align with standard tray configurations, reducing field fabrication and ensuring clean, continuous cable routing in both retrofit and new-install scenarios.

Key specs include catalog number 6A-42-90HB48, aluminum material, 90° angle, 48 in radius, 132.02 in length, 6 in height, and 42 in width. It weighs 39.6 lb and carries CE, CSA, and UL Classified certifications, making it a robust choice for durable cable management in demanding environments.

Yes. The 48 in radius supports smooth, low-stress routing over long runs, which is ideal for high-density installations. Its aluminum construction resists environmental challenges, helping maintain cable integrity and airflow. For facilities with space constraints, this bend minimizes sharp turns and reduces the risk of cable damage during installation and operation.

The bend is CE, CSA, and UL Classified certified, signaling compliance with major international safety and performance standards. This simplifies cross-border procurement, supports regulatory audits, and reduces risk when deploying in facilities that must adhere to stringent electrical and cable-management codes.

Plan for a straightforward alignment with existing B-Line trays, using compatible fittings and fittings assemblies to minimize field modifications. The 132.02 in length and 42 in width accommodate standard tray footprints, while the 48 in radius reduces rework from sharp corners. Proper handling of the 39.6 lb unit with standard tools speeds up installation and lowers labor costs over the system’s life.