Eaton B24A-120HDG Strut back-to-back welded channel - Hot-dipped Galvanized

Part Number: B24A-120HDG

Quick Summary

Eaton B24A-120HDG strut back-to-back welded channel provides rugged support for industrial racking and equipment mounting. In practice, installers face corrosion risk and time-intensive assembly in demanding environments, driving maintenance costs. This part uses hot-dipped galvanized steel in 14 gauge, delivering durable protection with a compact 12 in length, 3.25 in height, and 1.625 in width—dimensions that fit standard B-Line fittings. Certifications are listed as Not Applicable in the data; however, the galvanizing finish and steel construction align with general industry durability and compliance expectations. When paired with compatible fittings, it enables fast, scalable installations, lowering total installed cost and improving uptime for facilities relying on robust support structures.

Product Information

Extended Description

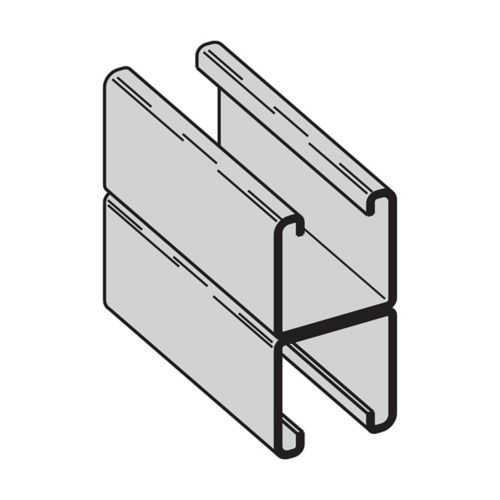

B24A-120HDG Eaton: Eaton B-Line series strut back-to-back welded channel, 1.62" H x 120" L x 1.62" W, Steel, Hot-dipped galvanized, 14 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B24A-120HDG

UPC

781011226084

Product Length/Depth

12 in

Product Height

3.25 in

Product Width

1.625 in

Product Weight

28.84 lb

Certifications

Not Applicable

Channel type

B24

Finish

Hot-dipped galvanized

Material

Steel

Material gauge

14 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B24A-120HDG

Dura-Green finish overview

Feature → Business Impact → Application: 14 Gauge steel and hot-dipped galvanized finish deliver corrosion resistance and structural integrity, extending service life in harsh environments while reducing maintenance cycles; ideal for heavy-use facilities and outdoor or semi-indoor installations, such as machinery mounting and racking. Feature → Business Impact → Application: Back-to-back welded channel design enhances load distribution and rigidity, improving safety margins and enabling longer spans between supports; suitable for cable tray support, equipment mounts, and modular racking in industrial plants. Feature → Business Impact → Application: 12 in length with precise 3.25 in height and 1.625 in width ensures compatibility with standard B-Line fittings and channel systems, simplifying procurement and installation in retrofit projects and new builds. Feature → Business Impact → Application: 14 Gauge steel provides predictable, robust performance, helping maintain compliance with general industry standards while reducing field adjustments and rework. Feature → Business Impact → Application: The hot-dip galvanizing finish minimizes corrosion exposure in harsh environments, lowering maintenance costs and extending equipment life. Feature → Business Impact → Application: Compatibility with Eaton’s B-Line system reduces total installed cost by enabling quick component swaps and scalable configurations for evolving facility needs.

Get a Quick Quote for a Eaton B24A-120HDG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B24A-120HDG?

Enquire Now

FAQs

This channel is designed to work with standard B-Line fittings and supports a straightforward installation process. Use compatible fasteners and hardware, verify anchorage points, and follow Eaton's mounting recommendations to ensure proper back-to-back alignment and load distribution. The hot-dipped galvanized finish also influences handling precautions to prevent paint/finish damage during assembly.

The 14 gauge steel provides solid load-bearing capacity for typical strut channel applications, while the hot-dipped galvanized finish offers excellent corrosion resistance in harsh environments. Together, they reduce maintenance needs and extend service life in facilities with exposure to moisture, chemicals, or outdoor conditions.

Yes. The B24A-120HDG back-to-back welded channel is designed for equipment mounting, rack support, and cable tray applications within industrial settings. Its dimensions—12 in length, 3.25 in height, and 1.625 in width—fit standard B-Line components, enabling reliable, scalable installations.

The provided data lists Certifications as Not Applicable. In practice, the product uses standard materials and finishes (14 gauge steel, hot-dipped galvanized) that align with general industry durability expectations. For formal regulatory compliance, verify project-specific standards with your quality team or Eaton’s specifications.

The combination of durable galvanizing, standard fit with B-Line components, and straightforward installation reduces maintenance frequency and field rework. Long-term, this can lower total installed cost (TIC) and improve uptime by simplifying retrofits, expansions, and ongoing system reliability in demanding facilities.