Eaton B24A-120SS4 B-Line Strut - Stainless 304

Part Number: B24A-120SS4

Quick Summary

The Eaton B24A-120SS4 B-Line back-to-back welded channel provides robust support for racking and overhead systems. Common challenges include misalignment, galvanic corrosion, and slow mounting due to inconsistent channel lengths. Certifications show Not Applicable, but the stainless steel type 304 finish and 14-gauge construction deliver corrosion resistance and load capacity. For procurement teams, the Eaton B-Line series simplifies jobsite installs and reduces long-term maintenance. The back-to-back welded design aligns fast with compatible channels, cutting installation time and improving system rigidity. Industrial buyers will appreciate the precise dimensions—12 inch length, 1.625 inch width, and 3.25 inch height—streamlining spec compliance. This combination supports scalable builds from small enclosures to large industrial frames.

Product Information

Extended Description

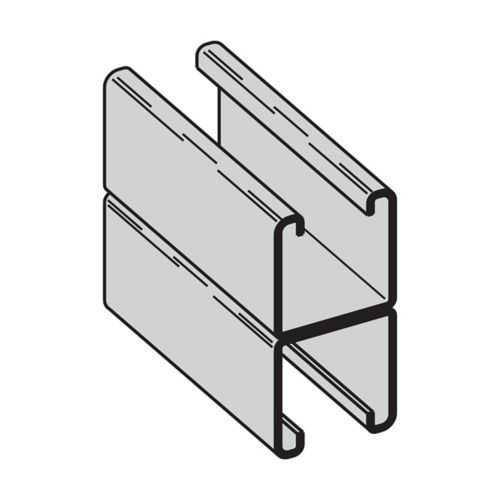

B24A-120SS4 Eaton: Eaton B-Line series strut back-to-back welded channel, 1.62" H x 120" L x 1.62" W, Steel, Stainless steel type 304, 14 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B24A-120SS4

UPC

781011226077

Product Length/Depth

12 in

Product Height

3.25 in

Product Width

1.625 in

Product Weight

28.84 lb

Certifications

Not Applicable

Channel type

B24

Finish

Stainless steel type 304

Material

Steel

Material gauge

14 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B24A-120SS4

Dura-Green finish overview

Feature: Back-to-back welded channel delivers exceptional rigidity and precise alignment for continuous, high-load installations across multi-panel systems. Business Impact: This minimizes deflection under load, reduces rework, and speeds commissioning on day one. Application: Utilize in overhead cable trays, control panels, and modular frame systems across facilities. Industry insight: The B24 profile aligns with standard fittings, cuts fabrication time, and lowers field risk. Feature: Stainless steel type 304 finish delivers robust corrosion resistance in harsh environments. Business Impact: Extends service life in wash-down zones and humid facilities, reducing maintenance cycles. Application: Suitable for food processing lines, chemical plants, and outdoor mounts facing moisture. Design note: 14 gauge steel balances strength with manageable weight during handling and install. Feature: 14 gauge metal supports high load capacity with minimal flex under typical industrial loads. Business Impact: Reduces need for additional bracing and costly retrofits, delivering clear lifecycle savings. Application: Ideal for mounting motors, drives, pumps, and large control panels in automation cells. Pro tip: Pair with matching connectors to maintain electrical continuity and grounding integrity. Feature: Precise dimensions—12 in length, 1.625 in width, and 3.25 in height—facilitate predictable fits. Business Impact: Speeds BOM creation, reduces mis-orders, and improves engineering confidence. Application: Streamlines prefabrication for racks, enclosures, and automation furniture across lines. Optimization: Validate tolerances with compatible components to avoid misalignment during final assembly. Feature: Compatibility with standard Eaton B-Line fittings accelerates project integration. Business Impact: Improves procurement efficiency, reduces stocking complexity, and enables scalable configurations. Application: Suits modular automation builds, data-center racks, and facility upgrades. Value driver: Modular assemblies support rapid upgrades and lower total cost of ownership.

Get a Quick Quote for a Eaton B24A-120SS4

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B24A-120SS4?

Enquire Now

FAQs

The B24A-120SS4 is designed to pair with standard Eaton B-Line series fittings and channels. To install, align back-to-back channels per the catalog section, use compatible fasteners, and verify that the channel faces are flush before securing. This approach minimizes misalignment and reduces field rework, especially in long runs or complex frames.

The B24A-120SS4 uses 14 gauge steel with a stainless steel 304 finish, delivering strong load-bearing performance suitable for heavy equipment mounts. Exact load ratings and tolerances are specified in the Eaton specification sheet (B24A-120SS4.pdf); consult the datasheet for precise numbers, installation guidance, and guidance on allowable deflection under typical industrial loads.

Yes. The stainless steel type 304 finish provides corrosion resistance suitable for moisture-rich environments, wash-down zones, and humid facilities. It combines durable strength with a finish that resists rust, helping extend service life in challenging areas such as food processing or chemical processing settings.

The product data shows Certifications as Not Applicable. While formal SIL, CE, or IP ratings are not listed, the stainless 304 finish and 14 gauge steel provide proven industrial performance. Always verify site-specific compliance requirements and confirm with Eaton’s datasheet for any project-specific standards.

The combination of corrosion resistance, high load capacity, and precise dimensions reduces maintenance cycles and replacement costs. Faster installation lowers labor costs during commissioning, while the durable finish minimizes corrosion-related repairs. Over a facility lifecycle, these factors contribute to lower total cost of ownership and improved system reliability.