Eaton B24A-240GLV Strut Channel - 14 Gauge, Pre-Galvanized

Part Number: B24A-240GLV

Quick Summary

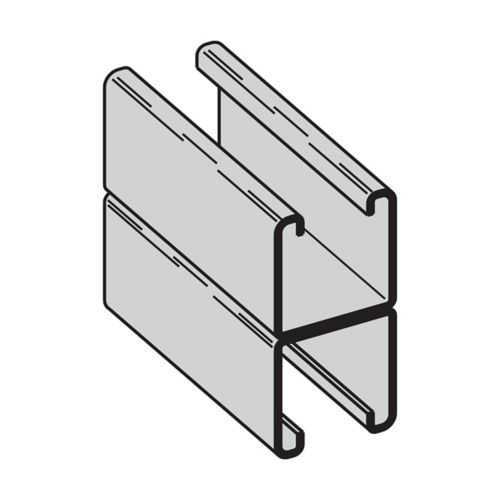

Eaton B24A-240GLV strut channel enables back-to-back framing for reliable electrical and mechanical support systems. Design challenges like misalignment, corrosion, and uneven load paths are common; this back-to-back welded channel provides robust, modular framing to reduce installation rework. Certifications are listed as Not Applicable, while the product uses 14-gauge steel with a pre-galvanized finish to resist corrosion and extend service life. When paired with Eaton's B-Line accessories, it delivers quick installation and scalable infrastructure for data centers, manufacturing floors, and facilities, delivering long-term value through modularity and ease of maintenance.

Product Information

Extended Description

B24A-240GLV Eaton: Eaton B-Line series strut back-to-back welded channel, 1.62" H x 240" L x 1.62" W, Steel, Pre-galvanized, 14 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B24A-240GLV

UPC

781011226350

Product Length/Depth

12 in

Product Height

3.25 in

Product Width

1.625 in

Product Weight

57.68 lb

Certifications

Not Applicable

Channel type

B24

Finish

Pre-galvanized

Material

Steel

Material gauge

14 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B24A-240GLV

Dura-Green finish overview

Feature: Back-to-back welded channel design for rigid framing. Business Impact: Improves load transfer and resistance to deflection, reducing field adjustments and rework. Application: Electrical and mechanical support rails in service corridors and equipment mounting areas. The pattern translates to faster installations and cleaner layouts in data centers and industrial facilities. Long-tail keyword focus: back-to-back welded strut channel, welded chassis in electrical install, rigid B-Line framing. Feature: 14 Gauge steel with pre-galvanized finish. Business Impact: Delivers durable, corrosion-resistant infrastructure suitable for indoor environments with reduced maintenance costs. Application: Commercial warehouses, manufacturing floors, and service bays using standard channel nuts and fittings. Feature: 12 in length with 3.25 in height and 1.625 in width. Business Impact: Modular segment design enables precise span configurations and easy customization on site. Application: Versatile mounting of panels, conduits, and equipment using compatible accessories. Feature: Catalog number B24A-240GLV and compatibility with B-Line ecosystem. Business Impact: Streamlines ordering and ensures seamless accessory compatibility, lowering project risk. Application: Retrofit projects and new builds requiring standardized strut channel components. Feature: Weight of 57.68 lb indicates robust capacity for heavy-duty applications. Business Impact: Supports heavy equipment and dense cable management with reduced sag and maintenance. Application: Industrial automation installations and data center rack framing. Feature: Not Applicable certifications. Business Impact: Clear expectation of product specification without over-promising compliance; users should verify project-specific standards. Application: Internal facility installations and environments where standard B-Line framing is acceptable. This set of features supports installation efficiency, compatibility with Eaton’s ecosystem, and reliable long-term performance.

Get a Quick Quote for a Eaton B24A-240GLV

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B24A-240GLV?

Enquire Now

FAQs

The B24A-240GLV is designed to work with Eaton’s B-Line series strut channel accessories, including channel nuts, bolts, and fittings. Its back-to-back welded construction provides a stable, modular backbone for mounting rails, panels, and equipment. When paired with compatible nuts and fittings, installation is quicker, with fewer misalignments and fewer on-site adjustments.

Back-to-back welded channels offer increased rigidity suitable for typical electrical and mechanical mounting tasks. For precise load ratings, refer to Eaton’s specifications and installation charts. The 14-gauge steel construction and 57.68 lb weight contribute to solid support, minimizing deflection under standard equipment loads and reducing the need for frequent retightening or rework.

The product uses a pre-galvanized finish, which provides corrosion resistance suitable for indoor commercial environments. For outdoor or highly aggressive conditions, additional protection or coatings may be required, and project teams should consult Eaton’s guidance and local standards to determine suitability and any needed supplementary treatments.

Certifications for the B24A-240GLV are listed as Not Applicable in the data provided. Users should verify project-specific regulatory requirements and consult Eaton for any equivalent standards or third-party certifications that may apply to their installation.

The combination of 14-gauge steel, pre-galvanized finish, and modular B-Line compatibility reduces maintenance needs by resisting corrosion and enabling quick reconfiguration. The back-to-back welded design lowers installation time and field adjustments, delivering ROI through faster project completion, easier future upgrades, and fewer spare parts for standard channel fittings.