Eaton B24A-240GRN Strut Channel - DURA GREEN

Part Number: B24A-240GRN

Quick Summary

Eaton B24A-240GRN strut channel is a robust back-to-back welded channel designed for reliable mounting in industrial and electrical installations. This solution helps engineers avoid misalignment and sag over long runs by delivering a precise 12 in length with a 1.625 in width and 3.25 in height, forged from 14 gauge steel and finished in DURA GREEN. Although this SKU lists Certifications as Not Applicable, B-Line products are typically evaluated to support CE and UL deployment within larger systems. For projects ranging from data centers to panel builds, this channel delivers consistent performance, corrosion resistance, and installation efficiency to drive measurable business value.

Product Information

Extended Description

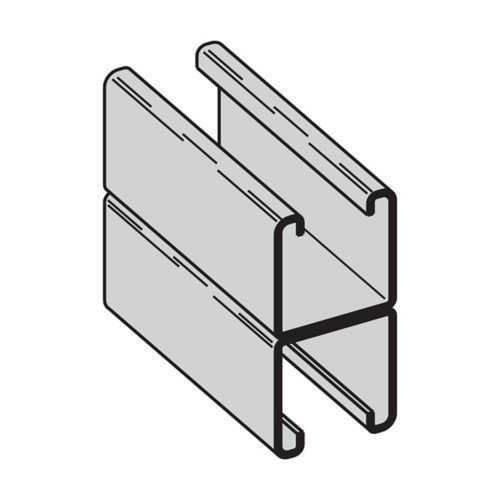

B24A-240GRN Eaton: Eaton B-Line series strut back-to-back welded channel, 1.62" H x 240" L x 1.62" W, Steel, DURA GREEN, 14 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B24A-240GRN

UPC

781011226251

Product Length/Depth

12 in

Product Height

3.25 in

Product Width

1.625 in

Product Weight

57.68 lb

Certifications

Not Applicable

Channel type

B24

Finish

DURA GREEN

Material

Steel

Material gauge

14 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B24A-240GRN

Dura-Green finish overview

Feature: Durable 14 gauge steel construction → Business Impact: Increased load-bearing capacity and long-term structural integrity reduce maintenance costs and downtime. Application: Electrical and mechanical support rails in control panels and racking systems. Feature: DURA GREEN finish → Business Impact: Enhanced corrosion resistance extends service life in moderate environments, lowering replacement cycles. Application: Indoor manufacturing environments and equipment rooms. Feature: Back-to-back welded channel design → Business Impact: Continuous, uniform support with reduced fatigue points improves reliability in long runs. Application: Perimeter framing and overhead support in data centers. Feature: Precise dimensions (12 in length, 1.625 in width, 3.25 in height) → Business Impact: Predictable fit with standard fittings speeds installation and reduces field customization. Application: Quick SKU deployments in standardized B-Line ecosystems. Feature: Broad documentation and compatibility → Business Impact: Faster engineering approvals and easier procurement through accessible catalogs and datasheets. Application: System design reviews and BOM preparation.

Get a Quick Quote for a Eaton B24A-240GRN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B24A-240GRN?

Enquire Now

FAQs

The B24A-240GRN is designed to work with standard Eaton B-Line strut channel fittings and accessories. Its back-to-back welded design accepts the same range of brackets, clamps, and connectors used across the B-Line family, enabling quick, reliable assembly in electrical and mechanical installations.

Catalog information lists a product length of 12 inches, height of 3.25 inches, and width of 1.625 inches, formed from 14 gauge steel. The listed product weight is 57.68 pounds, with a DURA GREEN finish. These specs support precise fitment and stable load paths in compact industrial setups.

The B24A-240GRN features a DURA GREEN finish, which provides enhanced corrosion resistance for indoor and semi-exposed applications. For extreme outdoor or highly corrosive environments, evaluate environmental conditions and consider additional protective measures or enclosure strategies as needed.

You can access multiple Eaton resources for this model, including the Channel and Combinations Catalog Section, the Eaton Specification Sheet for B24A-240GRN, and the Dura-Green finish overview. These files provide installation guidance, dimensional data, and finish details to support engineering and procurement.

Choosing Eaton B-Line strut channel delivers quick, modular installations with predictable fit, improved load distribution, and durable finishes that reduce maintenance. The back-to-back welded design supports longer spans with fewer fatigue points, which translates to accelerated project timelines and lower lifecycle costs in electrical and mechanical infrastructure.