Eaton B32A-120SS4 Strut Back-to-Back Welded Channel - Stainless 304, 12 Gauge

Part Number: B32A-120SS4

Quick Summary

Eaton B32A-120SS4 is a back-to-back welded strut channel for heavy electrical and mechanical support. In projects with space constraints or harsh environments, designers often struggle to find durable, install-ready channel solutions. Certifications for this variant are Not Applicable in Eaton’s catalog, so verify CE, SIL, or IP requirements before selection. Its stainless steel 304 finish and 12 gauge body offer corrosion resistance, while standard fittings enable fast, scalable deployment. This combination supports longer service life, reduced maintenance, and predictable installation timelines for industrial facilities, data centers, and manufacturing floors. Secondary keywords such as strut channel, B-Line, and industrial mounting are reinforced by these core features and business benefits.

Product Information

Extended Description

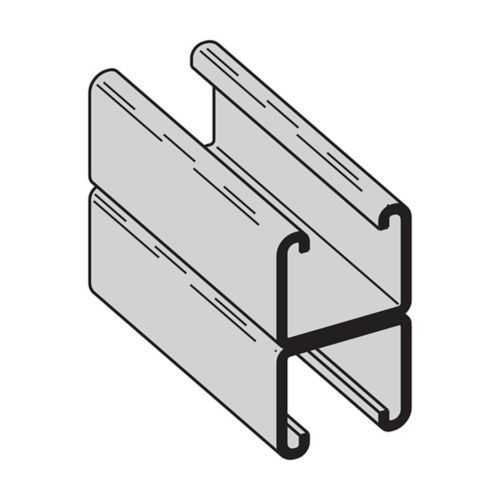

B32A-120SS4 Eaton: Eaton B-Line series strut back-to-back welded channel, 1.37" H x 120" L x 1.62" W, Steel, Stainless steel type 304, 12 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B32A-120SS4

UPC

781011844332

Product Length/Depth

12 in

Product Height

2.75 in

Product Width

1.625 in

Product Weight

34.67 lb

Certifications

Not Applicable

Channel type

B32

Finish

Stainless steel type 304

Material

Steel

Material gauge

12 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B32A-120SS4

Dura-Green finish overview

Feature back-to-back welded channel design → Business Impact reduces hardware counts and simplifies dual-row mounting, enabling cleaner cable trays and conduit runs. Application ideal for tight spaces in data centers and manufacturing floors. Feature stainless steel 304 finish with 12 gauge body → Business Impact delivers superior corrosion resistance and long-term durability in wet or washdown environments, lowering maintenance costs. Application suitable for process plants and cleanrooms where hygiene and longevity matter. Feature 12 in length x 2.75 in height x 1.625 in width with a weight of 34.67 lb → Business Impact provides predictable load capacity and rigid support for heavy equipment, improving installation confidence. Application for mounting large components and heavy conduits with minimal flex. Feature compatibility with standard fittings and Eaton catalog components → Business Impact accelerates procurement and reduces fabrication time, minimizing project schedules. Application across electrical, mechanical, and support systems installations. Feature industry context and real-world usage → Business Impact supports scalable solutions that adapt to evolving layouts, improving return on investment in facilities upgrade cycles. Application in retrofit projects where channel versatility matters. Feature natural resistance to common objections → Business Impact ensures installers can rely on consistent performance without bespoke solutions. Application in regulated environments where repeatability and standardization matter. Feature reference to Dura-Green finish overview → Business Impact communicates environmental considerations and finish choices that align with sustainability goals. Application in facilities seeking durable coatings for extended service life.

Get a Quick Quote for a Eaton B32A-120SS4

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B32A-120SS4?

Enquire Now

FAQs

The B32A-120SS4 is designed for heavy electrical and mechanical support in constrained spaces such as data centers, manufacturing floors, and plant rooms. Its back-to-back welded channel enables dual-row mounting, supporting conduits, cable trays, and equipment with strong load capacity. Use it where long-term corrosion resistance and reliable structural integrity are priorities to minimize maintenance downtime and maximize system uptime.

B32A-120SS4 is built to align with standard Eaton Channel and Combinations catalog components, ensuring straightforward procurement and a wide range of compatible fittings. This compatibility reduces fabrication time, simplifies splicing and extensions, and allows faster on-site assembly. For installers, this means fewer surprises during integration and a smoother project timeline.

According to Eaton’s catalog, the B32A-120SS4 lists certifications as Not Applicable for this variant. If your project requires CE, SIL, or IP ratings, verify with your procurement team or select an alternative model that explicitly meets those standards. Always align material selection with your facility’s safety and regulatory requirements to avoid compliance gaps.

Ensure proper alignment of both channel runs to prevent torsional stress in dual-row configurations. Use compatible fittings and hardware rated for 12 gauge steel and stainless finish to maintain corrosion resistance. Pre-assemble sections on the bench when possible, and plan for adequate support intervals to minimize deflection under load, improving long-term stability and reducing maintenance needs.

This model uses steel with a stainless steel type 304 finish and 12 gauge construction. The 304 stainless finish provides excellent corrosion resistance in moderate to harsh environments, including exposure to moisture and some chemical cleaners. The 12 gauge thickness offers robust structural strength, supporting heavy loads and long service life in demanding applications such as process areas and washdown zones.