Eaton B32A-120YZN Strut Back-to-Back Channel - 12 Gauge

Part Number: B32A-120YZN

Quick Summary

The Eaton B32A-120YZN is a back-to-back strut channel for mounting and supporting electrical systems. Engineers often contend with slow installs, misalignment, and corrosion resistance in demanding facilities, leading to project delays and higher maintenance costs. Certifications are Not Applicable for this catalog entry; for critical compliance needs, consult Eaton's datasheets to verify CE, SIL, or IP considerations. With a yellow zinc chromate finish and 12-gauge steel construction, this channel delivers durable support that simplifies installation while ensuring long-term reliability. Leveraging the B-Line series ecosystem, it enables scalable, modular framing that reduces downtime and streamlines procurement for ongoing electrical and mechanical initiatives.

Product Information

Extended Description

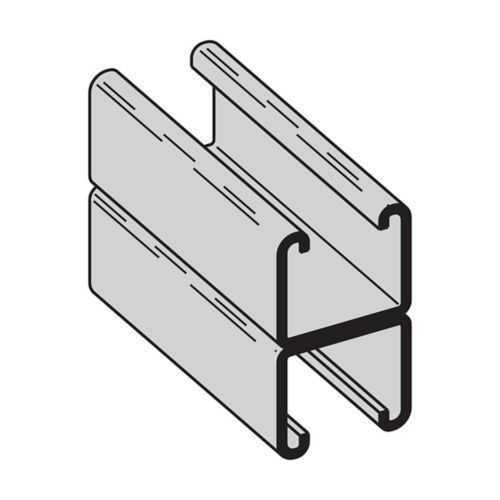

B32A-120YZN Eaton: Eaton B-Line series strut back-to-back welded channel, 1.37" H x 120" L x 1.62" W, Steel, Yellow zinc chromate, 12 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B32A-120YZN

UPC

781011046712

Product Length/Depth

12 in

Product Height

2.75 in

Product Width

1.625 in

Product Weight

34.67 lb

Certifications

Not Applicable

Channel type

B32

Finish

Yellow zinc chromate

Material

Steel

Material gauge

12 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B32A-120YZN

Dura-Green finish overview

Feature → Business Impact → Application: The B32A-120YZN is a 12-gauge steel back-to-back welded strut channel designed to bear substantial loads in a compact 12-inch length, delivering a rigid backbone for equipment, cable trays, and panel assemblies. This translates to improved structural integrity and faster mounting, reducing assembly time by aligning components with precision and minimizing rework on crowded enclosures or data centers. Applicationwise, it pairs with standard Eaton accessories to support consistent, code-compliant installations across manufacturing floors and industrial plants. A yellow zinc chromate finish provides corrosion resistance in wash-down or humid environments, lowering maintenance costs over the system life and extending service intervals. Compatibility with the B-Line ecosystem means you can source compatible fittings and brackets from a single vendor, simplifying procurement and reducing inventory complexity. The channel type B32 and its back-to-back welding enable flexible spacing and load distribution, addressing common objections about rigidity versus modularity in confined spaces. Industry insight shows that standardized, durable strut channels accelerate commissioning, improve safety margins, and deliver measurable ROI through reduced project duration and easier future upgrades.

Get a Quick Quote for a Eaton B32A-120YZN

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B32A-120YZN?

Enquire Now

FAQs

Installation starts with selecting compatible fittings and brackets from the B-Line series. Align the back-to-back channels to desired spacing, secure using standard strut hardware, and verify levelness with a straightedge. The 12 gauge steel and welded joint design provide a rigid frame suitable for panel racks, cable trays, and supports, while the yellow zinc chromate finish resists corrosion in typical industrial environments. This approach minimizes field adjustments and reduces commissioning time, delivering consistent results across multiple racks.

Key specifications include 12 in product length, 2.75 in height, 1.625 in width, 12 gauge steel, yellow zinc chromate finish, and catalog number B32A-120YZN. These dimensions define the channel footprint and load path, while the 12-gauge steel provides high stiffness and durability. The yellow zinc chromate coating offers corrosion resistance in humid or wash-down environments, contributing to longer service life and lower maintenance costs in industrial installations.

Yes. The B32A-120YZN is designed for back-to-back welded channel use within Eaton’s B-Line strut system, delivering a robust backbone for electrical and mechanical supports. Its 12 gauge steel construction and corrosion-resistant finish make it appropriate for manufacturing floors, machine bases, and control panels, where reliable load bearing, quick accessory compatibility, and standardized components help maintain uptime and safety compliance.

The catalog entry lists Certifications as Not Applicable. For projects requiring CE, SIL, or IP ratings, confirm specifications with Eaton’s official datasheets and your local regulatory requirements. Always verify that the final installation adheres to applicable electrical and mechanical code guidelines, and consult the Eaton specification sheet for any updates or alternate finishes that may impact compliance.

Using the B32A-120YZN in a system upgrade offers ROI through faster installation, reduced field rework, and extended lifecycle of the framing due to corrosion resistance from the yellow zinc chromate finish. Its compatibility with a wide range of Eaton accessories streamlines procurement and maintenance, enabling scalable upgrades without redesigning support structures. In practice, project timelines shorten, maintenance windows shrink, and total cost of ownership decreases over the equipment’s service life.