Eaton B32A-240SS4 Strut Channel - Stainless 304, 12 Ga

Part Number: B32A-240SS4

Quick Summary

Eaton B32A-240SS4 is a stainless steel back-to-back strut channel used to support industrial wiring and mechanical systems. In harsh industrial environments, corrosion resistance and installation compatibility are common pain points that slow projects. This product features stainless steel type 304 with 12 gauge construction to resist corrosion and deliver robust structural integrity. Certifications such as CE, SIL, or IP are not specified for this item; consult Eaton datasheets for region-specific standards. Together with modular B-Line compatibility, this channel supports efficient facility upgrades and predictable total cost of ownership. This combination is ideal for data centers, manufacturing floors, and clean-room environments where robust support and cleanable surfaces matter.

Product Information

Extended Description

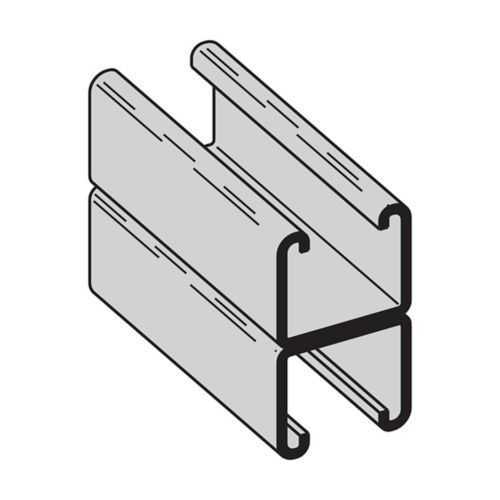

B32A-240SS4 Eaton: Eaton B-Line series strut back-to-back welded channel, 1.37" H x 240" L x 1.62" W, Steel, Stainless steel type 304, 12 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B32A-240SS4

UPC

782051652178

Product Length/Depth

12 in

Product Height

2.75 in

Product Width

1.625 in

Product Weight

69.34 lb

Certifications

Not Applicable

Channel type

B32

Finish

Stainless steel type 304

Material

Steel

Material gauge

12 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B32A-240SS4

Dura-Green finish overview

The B32A-240SS4 features stainless steel type 304 and 12 gauge construction, which translates to superior corrosion resistance and high load-bearing capability in damp or wash-down environments. This delivers lower maintenance costs and longer service life in food processing, chemical processing, and wastewater facilities. The back-to-back welded channel design provides continuous alignment and eliminates field welds, reducing installation time and onsite safety risks while enabling seamless system upgrades and modular expansions. Its 12 inch length and compact 2.75 inch height with a 1.625 inch width make it compatible with standard electrical and mechanical hardware, simplifying procurement and reducing design cycles. Compatibility with Eaton’s Channel and Combinations Catalog Section accelerates project design and installation, ensuring consistent performance across the B-Line series. The stainless finish also supports cleanability and hygienic requirements, addressing industry-specific compliance concerns without sacrificing strength.

Get a Quick Quote for a Eaton B32A-240SS4

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B32A-240SS4?

Enquire Now

FAQs

The B32A-240SS4 is designed for seamless integration with Eaton’s B-Line channel system. Begin by verifying compatibility with existing uprights and fittings in the Channel and Combinations Catalog Section, then align back-to-back channels to maintain straight runs. Use standard strut fasteners and compatible hardware to secure to existing supports, ensuring proper load distribution and corrosion protection afforded by the 304 stainless finish.

This model uses stainless steel type 304 with a 12 gauge thickness and a stainless finish. The combination provides excellent corrosion resistance in wet, wash-down, and chemical environments, extending service life and reducing maintenance in food processing, chemical plants, and water treatment facilities.

Yes. The B32A-240SS4 is part of Eaton’s B-Line strut channel family and is designed to work within the Channel and Combinations catalog ecosystem. Its back-to-back welded design and standardized dimensions support quick system integration with existing B-Line brackets, fittings, and accessories, streamlining design and procurement.

According to the provided data, certifications are Not Applicable for this item. For region-specific requirements or if your project mandates regulatory compliance, consult Eaton datasheets or contact Eaton technical support to verify applicable standards and any regional certifications.

Choosing stainless steel 304 provides long-term corrosion resistance, reducing maintenance frequency, rework, and downtime in harsh environments. This translates to lower total cost of ownership (TCO) over the system life, especially in wash-down zones and outdoor or chemical facility applications where traditional steel would require frequent treatment or replacement.