Eaton B42A-120GLV Strut Channel - 12 Gauge Pre-Galvanized Steel

Part Number: B42A-120GLV

Quick Summary

Eaton B42A-120GLV Strut Channel is a back-to-back welded channel for robust industrial electrical and mechanical mounting. When projects face misalignment, corrosion risk, or slow installation, this pre-galvanized, 12 gauge solution helps reduce rework and downtime. Certifications are not listed for this model; verify CE, UL, or IP options in the latest Eaton datasheets to ensure compliance in your environment. By integrating with standard B-Line hardware, you gain predictable performance, faster installs, and long-term reliability while maintaining compatibility with common fittings and accessories.

Product Information

Extended Description

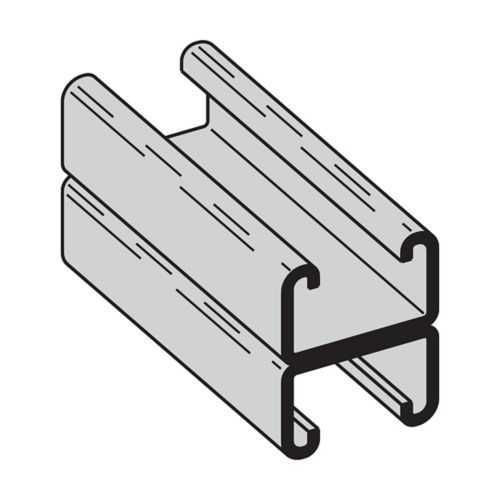

B42A-120GLV Eaton: Eaton B-Line series strut back-to-back welded channel, 1" H x 120" L x 1.62" W, Steel, Pre-galvanized, 12 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B42A-120GLV

UPC

781011247300

Product Length/Depth

12 in

Product Height

2 in

Product Width

1.625 in

Product Weight

29.36 lb

Certifications

Not Applicable

Channel type

B42

Finish

Pre-galvanized

Material

Steel

Material gauge

12 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B42A-120GLV

Dura-Green finish overview

Back-to-back welding creates a rigid channel that spans longer runs with fewer joints, delivering faster project completion and improved load-path reliability in electrical and mechanical supports. This robust geometry is paired with 12 gauge steel to resist deformation under heavy equipment mounting, translating to fewer replacements and safer installations. The pre-galvanized finish offers corrosion resistance for indoor environments, lowering maintenance costs and extending service life. With a 1" height, 2" width equivalent profile (1.625 in actual width) and a 12 in length, the channel integrates with standard fittings and connectors used across Eaton's B-Line system, enabling quick retrofits and modular configurations. Heavier-than-average weight (~29.36 lb) reflects its durability; plan for proper lifting and handling during on-site installation. The combination of compatibility, strength, and finish reduces total installed cost while improving long-term reliability across rack, enclosure, and support applications.

Get a Quick Quote for a Eaton B42A-120GLV

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B42A-120GLV?

Enquire Now

FAQs

The B42A-120GLV uses standard Eaton B-Line strut hardware and compatible fittings designed for 12 gauge steel back-to-back channels. For best results, match with Eaton connectors, brackets, and splice plates that specify B42 series compatibility to ensure proper load paths and secure mounting in racking and enclosure applications.

The channel is 12 inches long with approximately 2 inches of overall height and a width of about 1.625 inches, formed from 12 gauge steel. The weight is listed as 29.36 lb, reflecting its heavy-duty construction. Plan handling with appropriate lifting equipment and consider this weight when designing support spans and connection hardware for efficient installation.

Yes. The back-to-back welded channel design supports robust mounting and modular configurations typical in electrical rooms, machine mounts, and enclosure supports. Use the 12 gauge, pre-galvanized steel variant to balance rigidity with corrosion resistance in indoor, non-outdoor environments, and verify environment-specific requirements in Eaton datasheets.

The current data notes Certifications as Not Applicable. For regulatory compliance, consult the latest Eaton B-Line datasheets or contact Eaton support to confirm certified options or alternative models that meet CE, UL, or IP requirements for your specific jurisdiction and application.

Using pre-galvanized 12 gauge strut channels like the B42A-120GLV typically reduces maintenance and replacement costs due to improved corrosion resistance and longer service life. Coupled with faster installation thanks to compatibility with standard fittings, facilities can realize lower labor costs, shorter downtime during upgrades, and more reliable load-support over the system’s lifecycle.