Eaton B42A-120HDG Strut Back-to-Back Channel - 12 Gauge, Hot-Dipped Galvanized

Part Number: B42A-120HDG

Quick Summary

Eaton B42A-120HDG Strut provides rigid, back-to-back support channels for industrial rack, electrical, and mechanical installations. Users often face corrosion, maintenance costs, and compatibility gaps that slow project timelines. Note: the data for this model lists Not Applicable for Certifications, but B-Line systems commonly integrate with CE-marked components and IP-rated finishes in broader assemblies. With its hot-dipped galvanized steel and 12 gauge construction, this channel helps reduce lifecycle costs while enabling scalable, standards-aligned installations. In practice, operators benefit from compatibility with standard mounting hardware and Eaton accessories to accelerate commissioning and improve reliability across demanding environments.

Product Information

Extended Description

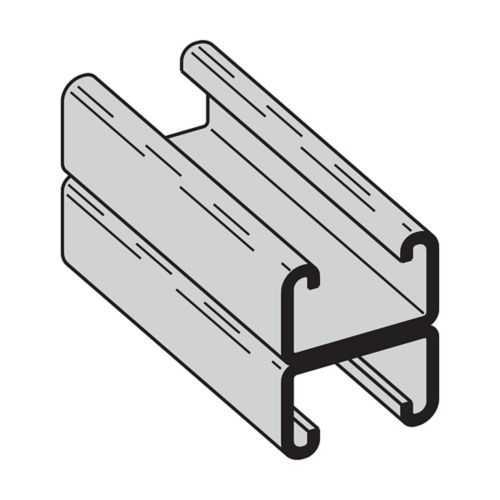

B42A-120HDG Eaton: Eaton B-Line series strut back-to-back welded channel, 1" H x 120" L x 1.62" W, Steel, Hot-dipped galvanized, 12 Gauge

Product Name

Eaton B-Line series strut back-to-back welded channel

Catalog Number

B42A-120HDG

UPC

781011247119

Product Length/Depth

12 in

Product Height

2 in

Product Width

1.625 in

Product Weight

29.36 lb

Certifications

Not Applicable

Channel type

B42

Finish

Hot-dipped galvanized

Material

Steel

Material gauge

12 Gauge

Channel and Combinations Catalog Section

Eaton Specification Sheet - B42A-120HDG

Dura-Green finish overview

Feature → Business Impact → Application: The back-to-back welded design increases stiffness and distributes loads more evenly, reducing deflection and enhancing overall rack integrity in mechanical and electrical installations. This translates to longer service life and fewer on-site adjustments during commissioning, particularly in manufacturing lines and data-center support applications. Feature → Business Impact → Application: 12 gauge steel with hot-dipped galvanized finish delivers superior corrosion resistance, lowering maintenance frequency and replacement costs in humid or outdoor environments, such as outdoor equipment enclosures and warehouse racks. Feature → Business Impact → Application: Precise dimensions (1 in height, 120 in length, 1.625 in width) enable predictable fit and straightforward integration with standard fittings, improving installation speed and reducing inventory complexity for system integrators. Feature → Business Impact → Application: Compatibility with Eaton B-Line components and common mounting hardware simplifies upgrades and reconfigurations in evolving facilities, supporting scalable, modular layouts without redesign. Feature → Business Impact → Application: The combination of durable construction and straightforward installation helps mitigate vibration-related wear and supports compliant, long-term electrical and mechanical support structures in industrial environments.

Get a Quick Quote for a Eaton B42A-120HDG

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton B42A-120HDG?

Enquire Now

FAQs

When installing the B42A-120HDG in back-to-back configurations, ensure proper alignment of channels, use compatible hardware from the Eaton B-Line family, and verify load path continuity. Avoid overtightening fasteners to prevent channel distortion, and plan joint locations to maintain continuous support across rack rows. This approach minimizes deflection and simplifies future reconfigurations for growing electrical or mechanical systems.

The 12 gauge steel provides solid load-bearing capacity with modest deflection under typical industrial loads, while the hot-dipped galvanized finish offers excellent corrosion resistance in humid, outdoor, or wash-down environments. Together, they reduce maintenance cycles, extend service life, and lower total cost of ownership for facilities such as manufacturing floors, warehouses, and outdoor data center enclosures.

Yes, the B42A-120HDG strut back-to-back channel is designed for modular support in electrical and mechanical assemblies, including enclosure framing and rack systems. Its compatibility with standard B-Line fittings and fittings simplifies integration into data centers and electrical rooms, while the galvanic protection and rigid construction support reliable, long-term performance in critical infrastructure.

The specific SKU notes Not Applicable for Certifications, but the B-Line strut system is commonly used with CE-marked components in compliant assemblies and can be paired with IP-rated finishes depending on system design. For regulatory compliance, verify the complete assembly meets your project’s local electrical and mechanical standards, and consult Eaton documentation for compatibility guidance with other certified components.

Investing in the B42A-120HDG back-to-back strut yields ROI through reduced installation time, fewer field adjustments, and extended lifecycle performance due to corrosion resistance. The standard dimensions and compatibility with existing Eaton fittings streamline procurement and maintenance, delivering faster commissioning, lower spare-part inventory, and improved system reliability over the project lifespan.