Eaton BCHID-GY32 Cable Hook Color ID Clip - cULus Listed

Part Number: BCHID-GY32

Quick Summary

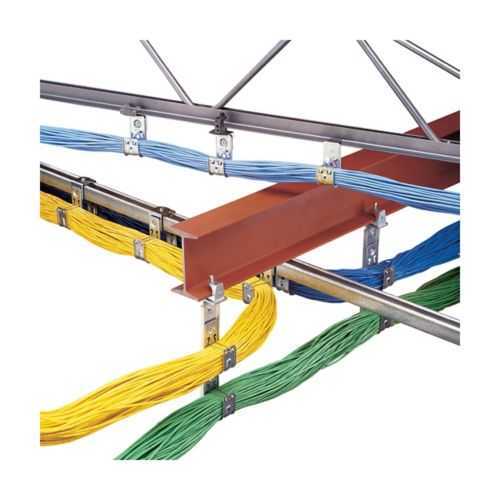

The Eaton BCHID-GY32 cable hook color id clip secures labeling for B-Line series enclosures, supporting clean, color-coded cable management. It helps prevent mislabeling and mixed-color wiring during installation, reducing traceability issues and maintenance delays. Certified cULus Listed under UL safety standards, this gray plastic clip is designed for durable, code-compliant panel work and easy integration with BCH32 accessories. For procurement and field service, the business value is clear: faster wiring audits, fewer rework incidents, and improved consistency across electrical rooms, panels, and data-center racks. By aligning with color-coding schemes and existing B-Line hardware, it streamlines installation workflows while supporting long-term reliability and safer, compliant installations.

Product Information

Extended Description

BCHID-GY32 Eaton: Eaton B-Line series box support fasteners, Plastic, Used with (BCH32), ID

Product Name

Eaton B-Line series cable hook color id clip

Catalog Number

BCHID-GY32

UPC

799038545002

Product Length/Depth

1 in

Product Height

2 in

Product Width

1 in

Product Weight

1 lb

Certifications

cULus Listed

Type

ID

Special features

Used with (BCH32)

Color

Gray

Durable plastic construction delivers long service life in harsh panel environments. This reduces replacement costs and minimizes downtime caused by wear or misplaced clips. It is well-suited for control panels, switchgear enclosures, and cable-run assemblies in manufacturing lines and data centers. Color-coded labeling with a gray finish supports rapid visual traceability, helping technicians quickly identify circuits and services during audits or maintenance. It works with BCH32 accessories and the B-Line series, simplifying installation and reducing the need for additional fastening hardware. At a compact 1 in L x 1 in W x 2 in H and 1 lb, the clip fits tight spaces without compromising cable pathways. The cULus Listed certification provides safety compliance for commercial and industrial panels, mitigating risk during inspections and routine servicing. In procurement terms, this clip minimizes SKU proliferation by aligning with existing Eaton B-Line inventory, delivering a straightforward path to compliant, scalable cable management.

Get a Quick Quote for a Eaton BCHID-GY32

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton BCHID-GY32?

Enquire Now

FAQs

Yes. BCHID-GY32 is designed for use with Eaton’s B-Line series box supports and is specifically mentioned as used with BCH32 accessories. The gray color ID clip integrates with existing B-Line hardware to streamline labeling workflows, reduce misidentification, and simplify field replacements without requiring additional fasteners or tools.

BCHID-GY32 measures 1 inch in length, 1 inch in width, and 2 inches in height, with an approximate weight of 1 pound. These compact dimensions fit tight panel spaces while providing durable identification in controlled environments, essential for reliable cable management in electrical enclosures.

Industries with dense electrical panels, data centers, and manufacturing line cabinets benefit most. The clip supports color-coding schemes and fast, visual identification of circuits, improving maintenance speed, reducing errors during audits, and aiding in compliance with safety labeling practices in industrial automation and power distribution setups.

BCHID-GY32 is cULus Listed, indicating it meets UL safety standards for electrical components. This certification helps ensure panel installations conform to regulatory safety requirements, supports safer maintenance procedures, and reduces compliance risk during inspections and audits in commercial and industrial facilities.

By enabling consistent color-coded labeling and rapid visual identification, BCHID-GY32 reduces troubleshooting and maintenance time, minimizes mislabeling errors, and accelerates audits. The result is lower labor costs, faster robot and technician interventions, and improved overall equipment uptime in control panels and distribution enclosures.