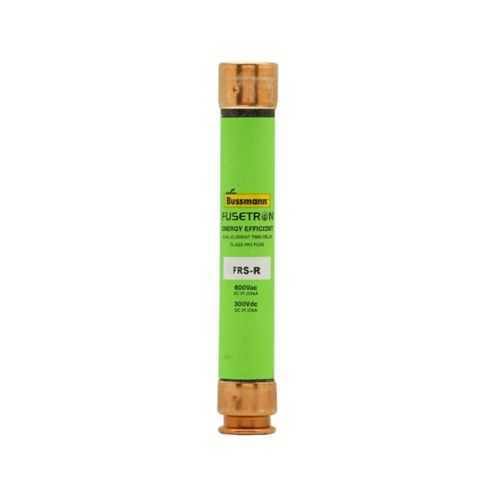

Eaton FRS-R-1/4 Fuse - Class RK5, CE Marked, 600 Vac

Part Number: FRS-R-1/4

Quick Summary

The Eaton FRS-R-1/4 fuse provides time-delay, current-limiting protection for industrial control circuits. Nuisance trips during motor starts or surges are a major pain point, and this fuse minimizes downtime without compromising safety. It is CE Marked and built as a Class RK5 dual-element device with rugged interrupt ratings up to 200 kAIC at 600 Vac and 20 kA at 300 Vdc. With ferrule-end connections, a compact 5 in length (0.81 in wide) and straightforward installation, it integrates smoothly into standard panel assemblies for reliable branch-circuit protection. This solution supports uptime, reduces nuisance faults, and preserves equipment in automotive, industrial automation, and process control environments.

Product Information

Extended Description

FRS-R-1/4 Eaton: Eaton Bussmann Series Class RK5 fuse, FRS-R, time-delay, dual-element, current limiting fuse, 0.25 A, non-indicating fuse, interrupting rating of 200 kA at 600 Vac and 20 kA at 300 Vdc

Product Name

Eaton Bussmann series FRS-R fuse

Catalog Number

FRS-R-1/4

UPC

051712507974

Product Length/Depth

5 in

Product Height

0.81 in

Product Width

0.81 in

Product Weight

0.15 lb

Warranty

Not Applicable

Compliances

CE Marked

Amperage Rating

0.25 A

Interrupt rating

20 kAIC at 300 Vdc 200 kAIC at 600 Vac

Response time

10 sec at 500%

Voltage rating

600 Vac, 300 Vdc

Number of elements

Dual

Packaging type

Standard

Class

Class RK5

Connection

Ferrule end x ferrule end

Fuse indicator

Non-indicating

Bussmann Full Line Catalog

Bussmann Full Line Catalog

RoHS Search Tool

Bussmann series Fuseology

Bussmann series FRS-R 600 V Class R up to 60 A fuse data sheet no. 1017

Feature: Time-delay, dual-element design. Business Impact: Reduced nuisance tripping during startup and short surges while maintaining robust protection. Application: Motor starters, pumps, fans, and other inductive loads in control panels. Feature: Current-limiting and high interrupt rating. Business Impact: Limits fault energy, protects downstream devices, and improves safety margins in high-inrush scenarios. Application: feeders, power distributions, and safety circuits in industrial plants. Feature: 600 Vac / 300 Vdc rating and 200 kAIC at 600 Vac, 20 kAIC at 300 Vdc. Business Impact: Reliable fault clearing in diverse power environments, enabling compliant protection schemes. Application: branch circuits across automation racks and machine controls. Feature: Ferrule-end x ferrule-end connections and 5 in length with 0.81 in width. Business Impact: Easy field installation and quick replacement, reducing downtime. Application: retrofit projects and new panel builds using standard RK5 holders. Feature: Non-indicating, standard packaging. Business Impact: Clean panel presentation and simple maintenance checks without visual fuse status indicators. Application: compact control enclosures and modular panels in manufacturing environments.

Get a Quick Quote for a Eaton FRS-R-1/4

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton FRS-R-1/4?

Enquire Now

FAQs

The FRS-R-1/4 uses ferrule-end x ferrule-end connections and a 5 in overall length, designed for standard RK5 fuse holders in control panels. It fits common Bussmann RK5 mounting patterns and simplifies field replacement with a compact, non-indicating body that minimizes panel intrusion.

It carries a 0.25 A amperage rating, is rated for 600 Vac and 300 Vdc, and provides high interrupt ratings of 200 kAIC at 600 Vac and 20 kAIC at 300 Vdc, with a 10-second response at 500% overload.

Yes, the fuse is CE Marked and built to the Class RK5 specification, indicating compliance with essential health and safety requirements for electrical equipment used in Europe and other markets that recognize CE.

Ideal for motor protection, control panels, and branch-circuit protection in automation environments, including manufacturing lines, process control systems, and power distribution within control cabinets.

Its time-delay, dual-element design reduces nuisance trips, while the high interrupt ratings and ferrule-end construction simplify replacement and upgrades. This translates to lower downtime, extended equipment life, and a favorable total cost of ownership in factory automation projects.