Eaton HLS-10 Fuse Holder - CE Marked RoHS Compliant

Part Number: HLS-10

Quick Summary

HLS-10 fuse holder from Eaton securely mounts and protects control-panel circuits. Engineers often struggle with secure connections, space constraints, and regulatory compliance in compact enclosures. This device carries CE Marked and RoHS Compliant certifications to help meet European wiring standards while delivering reliable fuse protection. With no flanges and compatibility with the GMT Type Indicating Series, it supports efficient panel layouts and streamlined installation, reducing harness complexity and improving overall reliability in industrial automation environments.

Product Information

Extended Description

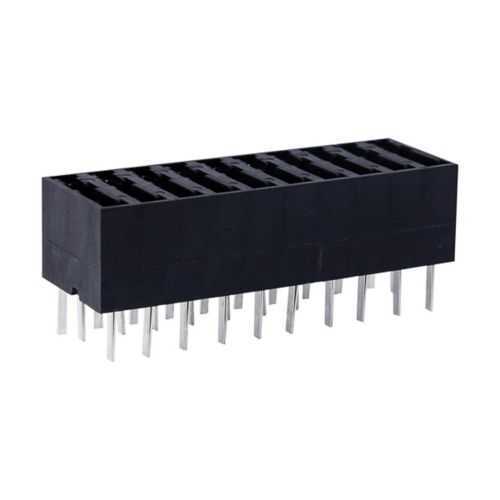

HLS-10 Eaton: Eaton Bussmann series HLS fuse holder, No flanges, 125 Vac, 60 Vdc, 15 A, Ten-pole, Tin-plated bifrucated copper terminal

Product Name

Eaton Bussmann series HLS fuse holder

Catalog Number

HLS-10

UPC

051712170017

EAN

5027590250696

Product Length/Depth

2.375 in

Product Height

1 in

Product Width

0.75 in

Product Weight

0.064 lb

Warranty

Not Applicable

Compliances

CE Marked RoHS Compliant

Amperage Rating

15 A

Voltage rating

125 Vac, 60 Vdc

Material

Tin-plated bifurcated copper terminal

Number of Poles

Ten-pole

Special features

No flanges

Used with

Used with GMT Type Indicating Series

Bussmann series complete full line catalog no. 1007

Bussmann series complete full line catalog no. 1007

Bussmann series Fuseology

Eaton Specification Sheet - HLS-10

Feature: Ten-pole compact design with a small footprint enables higher wiring density and tighter panel layouts. Business Impact: Reduces enclosure depth and simplifies harness routing, accelerating assembly and lowering labor costs. Application: Ideal for compact control panels in GMT Type Indicating Series installations. Feature: Tin-plated bifurcated copper terminal construction provides low contact resistance and corrosion resistance. Business Impact: Improves long-term reliability and reduces maintenance intervals in harsh industrial environments. Application: Suitable for high-cycle fuse protection in factory automation cabinets. Feature: Electrical ratings of 15 A at 125 Vac and 60 Vdc support standard control circuits while maintaining safe protection margins. Business Impact: Aligns with common industrial loads, minimizing the need for additional protective devices. Application: Protective interfaces for PLC I/O, motor control centers, and panel-based instrumentation. Feature: No flanges design simplifies mounting and reduces panel interference. Business Impact: Cuts installation time and enables snug fitments in tight spaces. Application: Common in GMT Type Indicating Series configurations where space is at a premium. Feature: General compliance with CE Marking and RoHS requirements lowers regulatory risk. Business Impact: Eases procurement and validation workflows for European customers and compliant OEMs. Application: Widely used in European equipment builds and RoHS-conscious manufacturing lines.

Get a Quick Quote for a Eaton HLS-10

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton HLS-10?

Enquire Now

FAQs

Install the HLS-10 in a suitable panel cavity designed for a ten-pole fuse holder. Mount using standard fasteners, connect the tin-plated bifurcated copper terminals to the circuit conductors, and verify the 125 Vac / 60 Vdc rating aligns with your load. The no-flanges design facilitates tighter mounting next to GMT Type Indicating Series indicators.

The HLS-10 is rated for 15 A at 125 Vac and 60 Vdc. Its physical footprint is 2.375 in long, 1 in high, and 0.75 in wide, with a weight of about 0.064 lb. It uses tin-plated bifurcated copper terminals for durable, low-resistance connections.

Yes. The HLS-10 is designed for use with GMT Type Indicating Series, enabling integrated fault indication and streamlined wiring in industrial control assemblies. Its compact, no-flange form factor complements GMT modules without adding panel thickness.

The HLS-10 features CE Marked and RoHS Compliant certifications. CE marking confirms conformity with European safety and performance standards, while RoHS ensures restricted hazardous substances compliance, reducing regulatory risk and facilitating international deployment.

With tin-plated bifurcated copper terminals, the HLS-10 offers good corrosion resistance and stable contact performance over time. There are no moving parts beyond the fuse interface, and the no-flanges design minimizes mechanical stress during vibration in industrial environments, supporting predictable lifecycle performance.