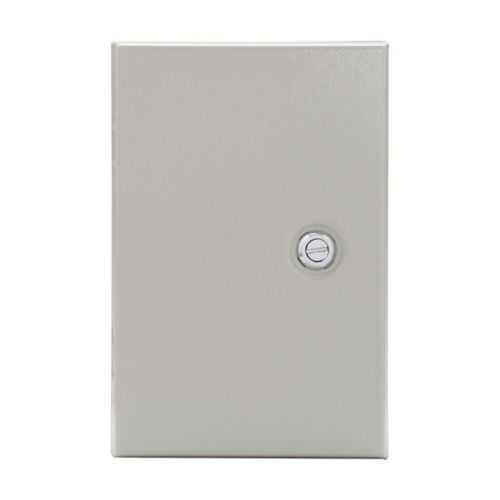

Eaton QBXS2403012UL Enclosure - IP66 & 4X Certified

Part Number: QBXS2403012UL

Quick Summary

The Eaton QBXS2403012UL enclosure protects electrical gear in hazardous locations, delivering rugged stainless-steel housing for control panels. When space is at a premium and ingress protection is non-negotiable, downtime and repair costs spike. Key certifications — IP66, NEMA 4X, and NEC/CEC compliance for Class I, Zone 2 and related hazardous locations — support safer, compliant installations. With a compact QBX footprint and corrosion-resistant material, this enclosure also offers installation flexibility and long-term value for industrial control systems.

Product Information

Extended Description

QBXS2403012UL Eaton: Eaton Crouse-Hinds series QBX enclosure, 4.72" depth, 15.75" x 11.81" x 4.72", 304 stainless steel

Product Name

Eaton Crouse-Hinds series QBX enclosure

Catalog Number

QBXS2403012UL

Product Length/Depth

11.81 in

Product Height

15.75 in

Product Width

4.72 in

Product Weight

10.74 lb

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Zone 2 Class II, Division 2 Class I, Division 2 Class II, Division 1 Class III

NEMA Rating

4X

Ingress protection (IP) ratings

IP66

Material

304 stainless steel

Depth

4.72 in

Enclosure size

15.75" x 11.81" x 4.72"

Crouse-Hinds series QBX Stainless Steel or Sheet Steel Enclosures catalog page

Eaton Specification Sheet - QBXS2403012UL

Feature: 304 stainless steel construction. Benefit: Superior corrosion resistance in chemical, washdown, and outdoor environments. Application: Ideal for chemical plants, oil & gas facilities, and water treatment control panels. The business impact is reduced maintenance cycles and extended service life, translating to lower total cost of ownership. Feature: IP66 ingress protection and NEMA 4X rating. Benefit: Proven protection against dust, water jets, and harsh washdowns, ensuring reliable enclosure performance. Application: Best suited for harsh production floors and outdoor installations. This improves uptime and minimizes unplanned outages, supporting safety compliance and predictable production schedules. Feature: Hazardous locations compliance (Class I, Zone 2; Class II, Division 1/2; Class III). Benefit: Regulatory alignment reduces risk of non-compliance penalties and enables safe operation in classified areas. Application: Chemical processing, petrochemical facilities, and mining environments. These certifications provide peace of mind for procurement, design reviews, and long-term asset protection. Feature: QBX family compatibility and compact footprint (15.75" H x 11.81" D x 4.72" W). Benefit: Easy mounting on standard rails or walls with minimal enclosure footprint. Application: Retrofit projects and modular control panel builds. This compatibility minimizes engineering changes and accelerates commissioning. Feature: 10.74 lb weight and 304 stainless steel finish. Benefit: Lighter handling during installation with durable, corrosion-resistant enclosure housing. Application: Repeated field service in challenging environments without sacrificing strength. This supports safer installations and lower maintenance risk.

Get a Quick Quote for a Eaton QBXS2403012UL

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton QBXS2403012UL?

Enquire Now

FAQs

For hazardous locations, ensure the enclosure is mounted on stable supports with proper gaskets and seals to maintain IP66/NEMA 4X protection. Provide adequate clearance for heat dissipation and wiring access, and use compatible QBX accessories where needed. Confirm NEC/CEC compliance and class/zone ratings for the specific site before commissioning.

Yes. The QBXS2403012UL is part of the Crouse-Hinds QBX family and supports compatible QBX accessories such as mounting adapters, gaskets, and hardware. This compatibility simplifies retrofits, reduces spare parts diversity, and streamlines procurement for projects using the QBX platform.

The enclosure carries IP66 and NEMA 4X ratings, plus NEC/CEC compliance for hazardous locations (Class I, Zone 2; Class II, Division 1/2; Class III). These certifications validate ingress protection, corrosion resistance, and safe operation in classified areas, supporting safety audits, insurance requirements, and regulatory adherence.

By using a corrosion-resistant 304 stainless steel enclosure with robust ingress protection, maintenance intervals can be extended and unplanned downtime reduced. The long service life of the enclosure lowers replacement frequency and spare-part costs, while simplifying compliance documentation and inspections—driving lower total cost of ownership over asset life.

Typical applications include housing for control panels, motor starters, and instrumentation in chemical plants, refineries, offshore platforms, and water/wastewater treatment plants. The combination of IP66/NEMA 4X protection and hazardous-location ratings makes it suitable for diesel yards, pump houses, and processing lines where moisture, dust, and corrosive agents are concerns.