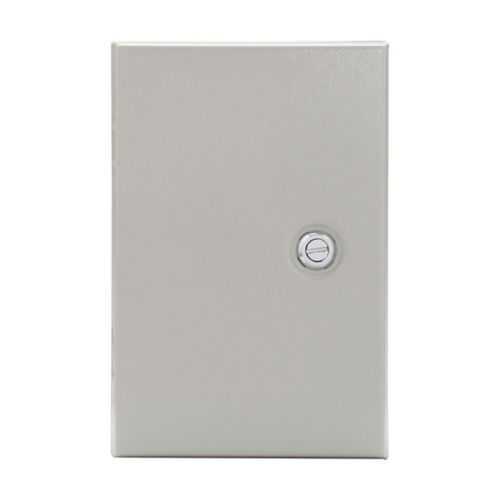

Eaton QBXS2504022UL Enclosure - IP66 4X Hazardous Locations

Part Number: QBXS2504022UL

Quick Summary

The Eaton QBXS2504022UL enclosure is a rugged stainless steel housing designed to protect electrical gear in harsh industrial environments. Engineers often battle corrosion, dust ingress, and costly downtime when equipment sits in hazardous locations. This QBX enclosure carries NEC/CEC compliance with hazardous ratings and a NEMA 4X enclosure rating, plus IP66 protection, adding confidence in severe service. It is built from 304 stainless steel to withstand exposure and has generous internal clearance for wiring and components. For automation projects, its robust construction supports process control panels, motor control centers, and instrumentation enclosures, delivering long-term reliability and lower lifecycle costs while simplifying maintenance and inspections.

Product Information

Extended Description

QBXS2504022UL Eaton: Eaton Crouse-Hinds series QBX enclosure, 8.66" depth, 19.68" x 15.75" x 8.66", 304 stainless steel

Product Name

Eaton Crouse-Hinds series QBX enclosure

Catalog Number

QBXS2504022UL

Product Length/Depth

15.75 in

Product Height

19.68 in

Product Width

8.66 in

Product Weight

19.19 lb

Area classification

Hazardous/Classified Locations

Standards type

NEC/CEC

NEC hazardous rating

Class I, Division 2 Class II, Division 1 Class II, Division 2 Class III Class I, Zone 2

NEMA Rating

4X

Ingress protection (IP) ratings

IP66

Material

304 stainless steel

Depth

8.66 in

Enclosure size

19.68" x 15.75" x 8.66"

Crouse-Hinds series QBX Stainless Steel or Sheet Steel Enclosures catalog page

Eaton Specification Sheet - QBXS2504022UL

304 stainless steel construction delivers superior corrosion resistance and washdown durability, reducing maintenance cycles and replacement costs in aggressive environments. The 4X/NEMA rating combination and IP66 protection mean the enclosure can withstand chemical splashes, humidity, and outdoor exposure without compromising seals or performance. This is essential for chemical plants, offshore facilities, and food-and-beverage processing lines where reliability matters most. Interior space and accessibility: The QBXS2504022UL offers 19.68 in height, 15.75 in depth, and 8.66 in width of usable interior space, combined with thoughtful gasket design. Generous clearance simplifies large terminal blocks, field wiring, and future upgrades, speeding assembly and reducing risk of miswiring. In motor control centers and process panels, technicians gain margin for neat cable routing and compliant spacing.Hazardous locations readiness: The enclosure carries extensive hazardous ratings (Class I Division 2; Class II Division 1 & 2; Class III; Zone 2) alongside NEC/CEC standards. IP66 and NEMA 4X further guard against dust, water, and corrosion. For oil, gas, chemical, and mining applications, this means safer installations, easier regulatory approvals, and less corrective action over the life of the equipment.Durability and maintenance advantages: Stainless steel construction resists denting and wear in demanding environments, while sealed closures and gaskets minimize ingress. The robust housing supports longer service intervals, reducing maintenance labor and downtime. For automation projects across manufacturing floors, enclosure integrity translates directly to higher uptime and safer operator environments.Installation and integration: Designed to align with QBX series form factors, enabling smoother integration with existing control panels and field devices. The combination of IP66, 4X, and hazardous-location ratings simplifies spec compliance and supports consistent engineering documentation. End-to-end, it lowers the total cost of ownership through better protection, simpler inspections, and predictable lifecycle performance.

Get a Quick Quote for a Eaton QBXS2504022UL

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton QBXS2504022UL?

Enquire Now

FAQs

Plan for proper clearance around the enclosure to maintain IP66 seals and allow airflow for any operating controls inside. Verify compatibility with NEC/CEC requirements for Class I Division 2 and Zone 2 environments, ensure correct mounting hardware, and use appropriate gaskets to preserve NEMA 4X protection during maintenance or resealing.

The enclosure provides generous interior space for wiring, terminal blocks, and instrumentation, reducing complexity during panel builds. Its stainless steel body resists corrosion, while IP66 and 4X ratings protect sensitive electronics in harsh plant conditions, improving reliability and uptime for automated processes.

It carries NEC/CEC compliance with hazardous ratings including Class I Division 2, Class II Division 1/2, Class III, Zone 2, along with NEMA 4X and IP66 protection. This combination supports code-compliant installations in oil, gas, chemical, and mining applications, reducing regulatory risk and expediting approvals.

The 304 stainless steel construction and rugged sealing reduce maintenance frequency and downtime, extending service life and lowering lifecycle costs. Its reliable protection minimizes inspection intervals and potential equipment repairs, delivering faster project amortization and overall equipment efficiency in demanding chemical-processing environments.

Industries with harsh environments and hazardous locations benefit the most, including oil and gas, chemical processing, mining, and heavy manufacturing. Applications span process automation panels, motor control centers, and instrumentation housings where corrosion resistance, ingress protection, and regulatory compliance are critical.