Eaton RH5 General purpose ventilated transformer - UL Recognized

Part Number: RH5

Quick Summary

Eaton RH5 is a general purpose ventilated transformer designed for powering control panels in industrial enclosures. In tight installations, heat buildup and limited access can threaten uptime and reliability, so a compact, ventilated solution is essential. The datasheet highlights UL Recognized certification, with specific relevance to CASE D rainhood enclosures, supporting safer panel builds. This combination of certification and enclosure compatibility reduces procurement risk while accelerating installation. By pairing a small footprint with proven safety credentials, RH5 delivers predictable performance, simplified sourcing, and rapid integration for electrical engineers and procurement teams working on modern automation projects.

Product Information

Extended Description

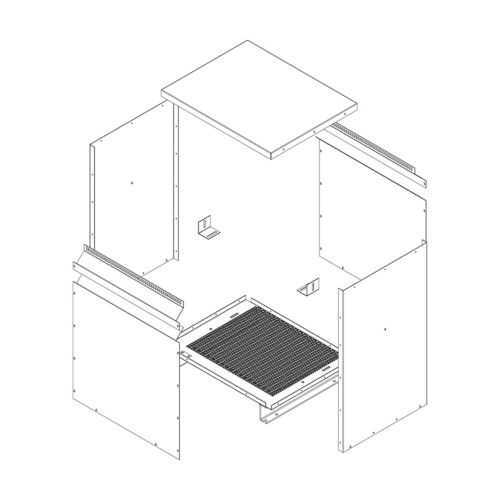

RH5 Eaton: TRANSFORMER RAINHOOD FOR CASE D

Product Name

Eaton General purpose ventilated transformer

Catalog Number

RH5

UPC

786689806422

Product Length/Depth

1.1 in

Product Height

1.1 in

Product Width

1.1 in

Product Weight

1.1 lb

Compliances

Not Applicable

Certifications

UL Recognized Not Applicable

Catalog Notes

ENCLOSURE FOR CASE D

Design

GENERAL PURPOSE

Frame

CASE D

Type

Rainhood

Application

XFMR RAINHOOD

Used with

CASE D

Rainhood enclosure design protects the transformer from incidental moisture and dust, enabling reliable operation in CASE D enclosures. This directly translates to reduced maintenance cycles and longer service intervals for XFMR RAINHOOD applications in harsh industrial environments. The compact footprint—1.1 in length, height, and width—coupled with a 1.1 lb weight, frees valuable panel space and simplifies mounting in densely populated control panels, improving overall enclosure efficiency and reducing cabinet footprint costs. UL Recognized certification validates electrical safety and compliance, lowering procurement risk and easing code adherence across industrial facilities. The RH5’s design is explicitly aligned with CASE D rainhood compatibility, ensuring straightforward installation and future upgrades without reworking enclosure interfaces. Finally, the product’s enclosure notes and “Used with CASE D” designation streamline part selection and spare-part planning for maintenance teams in manufacturing environments.

Get a Quick Quote for a Eaton RH5

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton RH5?

Enquire Now

FAQs

To install RH5, first verify CASE D compatibility and clearance for venting. Mount the transformer inside the enclosure using appropriate hardware, connect the primary and secondary leads per the factory wiring diagram, and ensure the rainhood remains unobstructed to maintain ventilation. Finally, confirm UL Recognized compliance and secure any access panels to preserve enclosure integrity.

RH5 has a compact footprint of 1.1 inches in length, height, and width, and weighs 1.1 pounds. The catalog number is RH5, and the UPC is 786689806422, which aids in quick part lookup and procurement across purchasing systems.

Yes. RH5 carries UL Recognized certification, indicating compliance with recognized safety standards for electrical components. This helps streamline approval processes in regulated facilities. No CE or IP ratings are listed in the data sheet for this model, so verify local code requirements when integrating with broader assemblies.

RH5 is designed as a general purpose ventilated transformer for XFMR RAINHOOD configurations and is specifically used with CASE D enclosures. Its rainhood design provides protection in environments where moisture or dust exposure is a concern, making it suitable for compact, panel-mounted power supply roles in automation and control systems.

RH5’s small size and ventilated design contribute to reduced space and cooling requirements, lowering enclosure cooling energy and maintenance overhead. UL Recognized certification reduces compliance risk, while CASE D compatibility speeds installation and future upgrades, delivering faster time-to-value for panel assembly and uptime improvements in manufacturing environments.