Eaton TP4Q10 Quick-Lok square outlet box - NEC/CEC

Part Number: TP4Q10

Quick Summary

The Eaton TP4Q10 Quick-Lok square outlet box is a durable 4 inch steel enclosure designed for reliable electrical terminations in industrial control panels. For engineers and electricians, misaligned knockouts and inadequate mounting options can trigger field rework and project delays. This unit is NEC/CEC compliant and rated for Ordinary/Non-Hazardous Locations, with UL certifications cited in product literature. Its welded steel body, ground bump, and 30.3 cu in capacity support code-compliant terminations in tight spaces, while its multiple side and bottom knockouts simplify conduit routing. Combined with compatible AC/MC clamps, it offers faster installs, easier future modifications, and long-term serviceability for factory automation environments.

Product Information

Extended Description

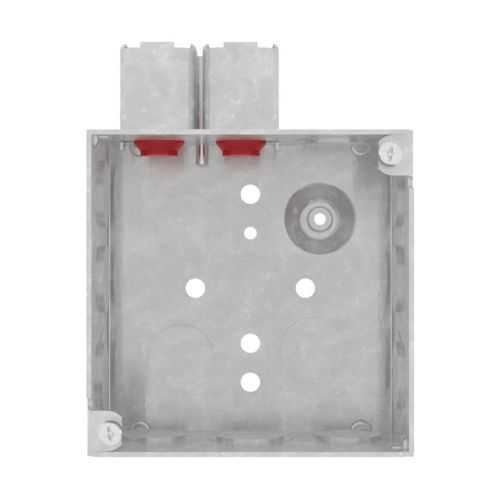

TP4Q10 Eaton: Eaton Crouse-Hinds series Quick-Lok 4" square outlet box, (2) 1/2", (2) 1/2"+ 3/4" E bottom KOs, Ground bump, 2 cable KOs, Welded, 2-1/8" depth, Steel, (6) 1/2", (4) 1/2" + 3/4" E side KOs, 30.3 cu in

Product Name

Eaton Crouse-Hinds series Quick-Lok square outlet box

Catalog Number

TP4Q10

UPC

662277114943

Product Length/Depth

5 in

Product Height

3 in

Product Width

4 in

Product Weight

0.98 lb

Area classification

Ordinary/Non-Hazardous Locations

Standards type

NEC/CEC

Box size

4"

Capacity

30.3 cubic inch capacity

Depth

2-1/8"

Conduit/cable

AC/MC clamps

Construction

Welded

Box ground wire

Ground bump

Side knockouts

(6) 1/2", (4) 1/2" + 3/4" E side KOs

Bottom Knockouts

(2) 1/2", (2) 1/2"+ 3/4" E bottom KOs

Cable knockouts

2

Material

Steel

Crouse-Hinds series Quick-Lok Outlet Boxes and Assemblies brochure

Crouse-Hinds series Quick-Lok Outlet Boxes and Assemblies catalog pages

4-Inch Steel Square Outlet Boxes, Covers, Extension Rings UL certification

4-Inch Steel Square Outlet Boxes, Covers, Extension Rings UL certification

Steel Outlet Boxes for Electrical Systems

Steel Outlet Boxes for Electrical Systems

Welded steel construction provides rugged protection against impact and dust ingress, reducing field damage and warranty risk while meeting NEC/CEC requirements in non-hazardous locations. This translates to lower maintenance costs and fewer unexpected downtime events in high-cycle manufacturing lines. The 4" box footprint, 2-1/8" depth, and 30.3 cubic inch capacity give engineers ample space for conductors, reducing the need for aggressive wire packing and enabling cleaner terminations in control panels. The configuration includes (6) side knockouts and (4) additional E side knockouts plus (2) bottom knockouts, plus bottom E knockouts, enabling flexible conduit routing and faster installation, especially when retrofitting existing cabinets. Ground bump and steel construction improve grounding reliability and code compliance across mixed-spec environments. AC/MC clamps compatibility supports quick, secure cable entries with minimal rework during panel upgrades or migrations. These features collectively reduce installation time, improve wiring quality, and lower lifecycle costs in automation projects.

Get a Quick Quote for a Eaton TP4Q10

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Eaton TP4Q10?

Enquire Now

FAQs

TP4Q10 is ideal for non-hazardous locations where reliable terminations and durable protection are required. Its welded steel construction, 30.3 cu in capacity, and multiple knockouts support clean wiring runs in machine panels and control cabinets, helping minimize field modifications and downtime.

TP4Q10 offers (6) side knockouts and (4) side E knockouts, plus (2) bottom knockouts and (2) bottom E knockouts, along with 2 cable knockouts. This configuration provides flexible conduit routing for complex wiring while maintaining a compact 4" box footprint suitable for tight panel spaces.

TP4Q10 is rated for Ordinary/Non-Hazardous Locations and adheres to NEC/CEC standards. It is not specified for hazardous (explosive) atmospheres. For hazardous locations, a variant with appropriate ratings or enclosures designed for those classifications should be selected.

The TP4Q10 complies with NEC/CEC standards and is UL certified for steel square outlet boxes. It is intended for ordinary/non-hazardous locations, ensuring code-compliant grounding, wiring practices, and safe enclosure integrity across cross-border installations.

Key considerations include leveraging the ground bump for solid grounding, using AC/MC clamps compatible with the knockouts for quick entry, and planning knockouts to minimize wire bending and conductor fill. The welded construction and 2-1/8" depth help maintain panel density, while the 30.3 cu in capacity accommodates future cable expansion without reworking the enclosure.