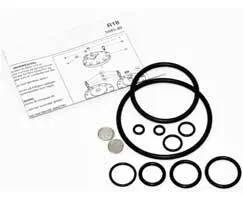

Norgren 5945-40 Service Kit - R18

Part Number: 5945-40

Quick Summary

Norgren 5945-40 service kit provides essential maintenance for R18 pneumatic components used in automated production lines. Without proper service parts, downtime spikes and seal wear accelerates, leading to unpredictable performance and higher maintenance costs. In practice, teams look for CE conformity and IP-rated enclosures when servicing R18 units, and SIL safety considerations are common in safety-critical lines. The kit’s compatibility with the R18 range streamlines procurement, reduces spare-parts inventory, and supports lean maintenance programs for industrial automation teams, delivering tangible gains in uptime and operational reliability.

Product Information

Range

R18

Brand

IMI Norgren

Feature → Business Impact → Application: OEM-aligned R18 maintenance kit tailored for IMI Norgren R18 systems. Business Impact: Ensures accurate, drop-in replacements, reducing the risk of incorrect seals and part incompatibilities that cause downtime. Application: Use during scheduled maintenance on R18 actuators and valves to preserve performance and extend service life in high-cycle automation lines. Feature → Business Impact → Application: OEM-grade seals and components designed for R18 service. Business Impact: Longer seal life, lower leakage rates, and fewer unplanned outages. Application: Ideal for packaging, material handling, and robotic cells where consistent pneumatic response is critical. Feature → Business Impact → Application: Simple, tool-light installation and replacement. Business Impact: Short maintenance windows and reduced labor costs, enabling faster changeovers. Application: Field service teams can complete preventive maintenance without specialized tooling, keeping lines running with minimal disruption. Feature → Business Impact → Application: Streamlined procurement with a single part number. Business Impact: Lower inventory levels and faster replenishment, improving supply chain resilience. Application: Manufacturing plants seeking lean spares strategies in multi-plant deployments benefit from this approach. Feature → Business Impact → Application: Broad compatibility with Norgren components and the R18 ecosystem. Business Impact: Reduces part-mismatch risk across mixed fleets and simplifies retrofits. Application: Retrofit projects and preventive maintenance programs across automated lines using R18 hardware.

Get a Quick Quote for a Norgren 5945-40

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren 5945-40?

Enquire Now

FAQs

Yes. The 5945-40 is specifically designed for the R18 range and provides OEM-aligned parts that ensure proper fit and function with IMI Norgren R18 actuators and valves. Using the correct kit reduces the risk of mismatched seals or components, minimizing downtime and return visits for part corrections. Always verify the R18 model variant before replacement to ensure full compatibility.

Expect measurable improvements in actuation reliability and reduced leakage due to OEM-grade seals and components tailored for the R18 system. Scheduled maintenance with the correct kit also shortens repair windows, lowers unplanned downtime, and stabilizes pneumatic response on high-cycle lines such as packaging and material handling equipment.

The kit is ideal for industrial automation environments where Norgren R18 pneumatic systems are deployed, including packaging, robotics, and assembly lines. It supports typical factory conditions and is compatible with the broader R18 ecosystem, helping maintain consistent performance across multiple machines and cells.

Certification context for maintenance kits in this category commonly references CE conformity and general industry standards for pneumatic components. While this kit aligns with OEM practices for R18 systems, regional compliance should be confirmed by your QA team, especially for safety-critical applications where SIL considerations may apply to the broader machinery.

Using an OEM-aligned service kit like 5945-40 reduces downtime, extends seal life, and lowers the risk of incorrect part substitutions. These factors translate into lower maintenance costs, shorter replacement cycles, and improved overall equipment effectiveness (OEE). Over time, the streamlined procurement and faster spares replenishment further improve ROI for high-demand manufacturing environments.