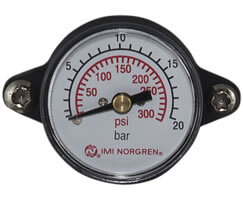

Norgren 840073-02KIT Integrated Gauge - 20 bar

Part Number: 840073-02KIT

Quick Summary

Integrated Gauge technology from Norgren delivers precise pressure monitoring for compact pneumatic systems used in manufacturing and automation. Engineers often struggle with bulky gauges and difficult installations, and this Excelon Plus integrated gauge simplifies mounting while delivering reliable feedback for control loops. This family aligns with common industry safety and quality expectations, with reference to standard compliance pathways such as CE marking and robust enclosure protection where applicable. By combining sensing, signaling and a compact footprint, the solution reduces downtime, lowers maintenance costs, and supports scalable automation across lines and workcells. The result is faster commissioning, easier field service, and improved process reliability for real-world industrial environments.

Product Information

Maximum Inlet Pressure

20 bar

Dimensions - Height

20 mm

Dimensions - Length

52 mm

Dimensions - Width

35 mm

Weight

0.021 kg

Country of Origin

United Kingdom

Series

Excelon Plus

Brand

IMI Norgren

Feature → Business Impact → Application: The Excelon Plus Integrated Gauge delivers a compact 52 mm length and 35 mm width footprint, enabling installation in tight control panels and space-limited enclosures. This translates to faster panel routing, reduced assembly time, and improved serviceability in high-density layouts used in packaging, automation cells, and process lines. Feature → Business Impact → Application: With a maximum inlet pressure of 20 bar, this gauge supports standard pneumatic systems without overdesign, reducing one-off component costs and allowing similar instrumentation across multiple lines. Feature → Business Impact → Application: The lightweight 0.021 kg build minimizes mounting stress on brackets and reduces overall weight load on movable assemblies, enhancing vibration resistance and easing tilt or rotate mounting on conveyors and handling equipment. Feature → Business Impact → Application: Excelon Plus branding and UK origin provide traceable quality and consistent documentation, streamlining supplier qualification and compliance checks for aerospace, automotive, and general manufacturing. Feature → Business Impact → Application: The integrated gauge comes with an Installation Guide PDF, simplifying onboarding, installation accuracy, and field maintenance, which improves first-time fix rates and reduces downtime.

Get a Quick Quote for a Norgren 840073-02KIT

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren 840073-02KIT?

Enquire Now

FAQs

The 840073-02KIT is designed as part of the Excelon Plus family and integrates with standard Norgren pneumatic manifolds and controllers. Its compact 52x35x20 mm footprint fits common panel layouts, and the included installation guide provides step-by-step mounting and connection procedures to ensure proper alignment with existing ports and sensors.

Key specs include a maximum inlet pressure of 20 bar, dimensions of 52 mm (length) x 35 mm (width) x 20 mm (height), and a weight of 0.021 kg. The unit is configured for the Excelon Plus series and is manufactured in the United Kingdom, providing a compact, lightweight sensing solution for pneumatics applications.

Ideal for automated manufacturing, packaging lines, pneumatic valve actuation, and process control where compact pressure monitoring is required. The small form factor and integration in the Excelon Plus line support dense control panels, line-side sensing, and quick commissioning in environments demanding dependable feedback for automation loops.

Certification availability depends on configuration and regional requirements. Common industry practice includes CE-marking for safety and compliance; IP protection and SIL-based assessments are typically determined by the overall system enclosure and safety architecture. Consult the Installation Guide and your regional compliance team for exact certification details on your configuration.

By providing accurate, integrated pressure monitoring in a compact package, the gauge reduces field wiring complexity, shortens commissioning time, and lowers maintenance visits due to simplified diagnostics. Over multiple lines, this translates to lower total cost of ownership and faster downtime recovery in high-uptime manufacturing environments.