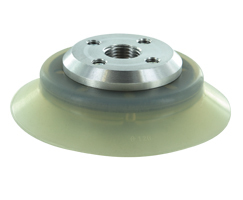

Norgren M/58311/02 Flat Suction Cup - G1/2 Port 120 mm

Part Number: M/58311/02

Quick Summary

Flat suction cup M/58311/02 delivers a reliable vacuum grip for delicate, pliable materials in automated pick-and-place tasks. In tight fixtures, maintaining consistent suction and avoiding material damage can be a challenge. Industry standards often require CE conformity for European operations, SIL safety validation for automated handling, and adequate ingress protection where exposure to dust or moisture occurs. This cup is designed for compatibility with Norgren vacuum systems and common pneumatic fixtures, offering a robust, long-lasting solution that minimizes cycle time and scrap. By combining a 120 mm diameter contact area with a G1/2 port, it delivers reliable performance across diverse manufacturing lines while supporting scalable automation costs.

Product Information

Extended Description

M/58311/02 Norgren: Flat cups ideal where minimal movement is required for pliable materials

Medium

Vacuum

Operating Temperature

-30 ... 200 °C, -22 ... 392 °F

Port Size

G1/2

Diameter

120 mm

Materials - Body

Aluminium

Materials - Elastomers

Silicone

Range

M/58300

Series

Norgren Vacuum

Brand

IMI Norgren

Feature: G1/2 port compatibility aligns with standard vacuum fittings, enabling quick, reliable connections. Business Impact: Reduces installation time and leakage risk, boosting overall line uptime and lowering maintenance costs. Application: Ideal for robotic grippers, fixture plates, and conveyor-fed pick-and-place stations in automotive, electronics, and packaging environments. Feature: 120 mm diameter flat face provides a generous contact area for stable gripping of pliable materials. Business Impact: Improves hold strength while minimizing deformation, reducing scrap and part damage. Application: Particularly effective for films, foils, and soft plastics on high-speed assembly lines. Feature: Aluminium body with silicone elastomer offers a durable, lightweight construction with reliable elasticity across temperature extremes. Business Impact: Extends service life in demanding environments and maintains seal integrity for consistent vacuum performance. Application: Suitable for high-temperature processes up to 200 °C and cold cycles, enabling broad process compatibility. Feature: Part of the Norgren Vacuum family (Range M/58300) ensures compatibility with existing components and common maintenance practices. Business Impact: Reduces procurement risk, inventory variety, and training needs; supports scalable automation. Application: Integrates with Norgren vacuum regulators, chucks, and hoses across multiple lines. Feature: Temperature range and material selection enable reliable operation across varied industries; Silicone elastomer provides good chemical resistance and resilience. Business Impact: Helps meet process constraints, lowers replacement frequency, and supports lean manufacturing. Application: Suitable for packaging, electronics assembly, automotive fixtures, and general manufacturing lines requiring consistent suction.

Get a Quick Quote for a Norgren M/58311/02

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren M/58311/02?

Enquire Now

FAQs

Mounting M/58311/02 with standard G1/2 vacuum fittings is straightforward. Use a flat, clean mounting surface and align the cup concentric with the gripping face. Tighten fittings to recommended torque to avoid leaks, and verify compatibility with your controller’s vacuum level. This approach minimizes cycle errors and reduces gasket wear in high-speed lines.

This cup operates from -30 to 200 °C and uses a silicone elastomer that remains flexible across temperature changes. For best results, ensure cure times and vacuum levels are appropriate for your material. The combination supports reliable performance on hot plastics and cold-assisted processes, maintaining grip without frequent replacement. It tolerates typical process fluids under standard conditions.

Yes. The large 120 mm diameter flat face provides stable contact on pliable packaging like films and foils, reducing suction loss during fast cycles. For ultra-thin materials, consider adjusting vacuum level and dwell time to avoid downstream deformation while maintaining throughput. The silicone elastomer aids in gentle yet durable grips across cycles.

The data sheet lists vacuum medium, operating temperature, port size, and materials; explicit CE, SIL, or IP certifications are not shown. Verify applicable certifications in your region by consulting the datasheet and supplier approvals. In practice, Norgren’s broader product family commonly supports CE compliance in European markets, but regional validation is recommended for regulatory assurance.

Upgrading to a silicone-elastomer cup with robust aluminium body reduces scrap and tool wear by delivering consistent grip across cycles and temperatures. Lower maintenance and longer service life translate into reduced downtime, lower replacement costs, and a faster return on investment for automation lines handling delicate or variable materials.