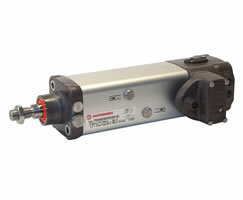

Norgren PRA/882050/MIB/M4/200 IVAC Cleanline Cylinder - IP67

Part Number: PRA/882050/MIB/M4/200

Quick Summary

The PRA/882050/MIB/M4/200 IVAC Cleanline cylinder provides precise, dependable linear actuation for automated packaging and assembly. Too often, wear and energy waste from conventional cylinders drive maintenance costs and downtime. Designed with ISO 15552 compatibility and IP67 protection, plus magnetic cylinders and adjustable cushioning, it delivers longer life and predictable performance. This combination translates to lower air consumption, simpler installations, and a faster return on automation investments. By leveraging ISO 15552 compatibility and quick electrical connections via Norgren's M/50 switches, maintenance teams can streamline spares and calibration. In practice, users see improved cycle stability, reduced leakages, and consistent force across the stroke for high-precision pick-and-place tasks.

Product Information

Extended Description

PRA/882050/MIB/M4/200 Norgren: Cleanline Profile barrel with integrated switches | Glandless spool valve for extended life and high performance | Adjustable flow regulator for speed control | Incorporates Norgren M/50 switches | Single air and electrical connection for quick, simple installation | Cylinders and mountings conform to ISO 15552 (length, mounting pitch and thread dimensions according to ISO 15552. Some outside dimensions different to ISO 15552) | Can potentially reduce air consumption by up to 50% compared to conventional systems

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

2 ... 8 bar, 29 ... 116 psi

Standard

ISO 15552

Port Size

G1/8

Actuation

Solenoid pilot / Solenoid pilot

Cylinder diameter

50 mm

Stroke Length

200 mm

Operation

Double acting

Valve operation

5/2

Cushioning

Adjustable cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

1178 N

Materials - Barrel

Anodised aluminium

Materials - Piston Rod

Stainless steel

Certification - IP Rating

IP67

Dimensions - Height

109 mm

Dimensions - Length

375 mm

Dimensions - Width

92.5 mm

Weight

3.02 kg

Country of Origin

Germany

Range

PRA/882000

Series

IVAC

Brand

IMI Norgren

C0K510828

Pneufit C Push-in fitting, Banjo flow control, regulating out, 8mm, G1/4

C02250828

Pneufit C Push-in fitting, Adaptor, Straight, External/Internal hex, 8mm, G1/4

C02470828

Pneufit C Push-in fitting, Adaptor, 90° Swivel elbow, 8mm, G1/4

M/3314

Tube cutter

PA2-0008025C

Polyamide tube, Natural, 25m, 8mm/6mm

Feature: Dual solenoid pilot actuation (5/2 valve) → Business Impact: Faster, more reliable control of pneumatic flow with reduced signal delay → Application: High-speed packaging lines and precision pick-and-place tasks. The result is improved cycle times and repeatable movements. Feature: Glandless spool valve design → Business Impact: Lower wear, extended life, and reduced maintenance intervals → Application: Harsh industrial environments where debris or particulates are present. Feature: Adjustable cushioning → Business Impact: Smoother deceleration and reduced mechanical shock → Application: Delicate placement operations and high-speed cycles where impact must be controlled. Feature: Integrated M/50 switches and single electrical connection → Business Impact: Simplified wiring, faster installation, and lower wiring errors → Application: Quick-start automation cells and retrofit projects. Feature: ISO 15552 compatibility and 50 mm bore → Business Impact: Interchangeability with standard actuators, faster parts replacement, and predictable mounting → Application: Automated lines needing modularity and spare parts commonality. Feature: IP67 rating and magnetic piston → Business Impact: Washdown-ready reliability with robust protection against ingress and magnetic sensing for in-line sensing → Application: Food & beverage, pharma, and outdoor or dirty environments. Feature: High theoretical force of 1178 N → Business Impact: Sufficient actuation force for larger grippers and clamping tasks without oversized cylinders → Application: Robotic end-effectors and custom fixtures in winding, sealing, or assembly lines. Feature: 2–8 bar operating pressure range → Business Impact: Flexible deployment across systems with varying air pressure supply → Application: Retrofit projects where pressure stability varies. Feature: 50 mm cylinder diameter and 200 mm stroke → Business Impact: Balanced stroke length with compact footprint and broad reach → Application: Linear actuations on conveyors, indexing stations, and transfer mechanisms.

Get a Quick Quote for a Norgren PRA/882050/MIB/M4/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren PRA/882050/MIB/M4/200?

Enquire Now

FAQs

This cylinder is designed to be ISO 15552 compatible, with standard mounting pitches and threads to align with common automation frames. The G1/8 ports simplify plumbing, and the integrated M/50 switches reduce external wiring. When retrofitting existing lines, verify mounting dimensions (length, height, and width) and ensure your control cabinet can accommodate the single electrical connection for quick commissioning.

Operating pressure is 2 to 8 bar (29 to 116 psi). Theoretical force is 1178 N, which supports reliable linear actuation for medium to high-load applications. The 50 mm bore and 200 mm stroke provide a balanced combination of force and travel for typical pick-and-place and clamping tasks.

Yes. The double-acting design, adjustable cushioning, and magnetic piston enable precise stopping and repeatable motion ideal for pick-and-place operations. Its compact 50 mm bore and 200 mm stroke fit many packaging and indexing stations, while ISO 15552 compatibility ensures easy integration with standardized mounting and quick part replacements.

Key certifications include IP67, indicating excellent protection against dust and water ingress, and ISO 15552 compliance for standardized cylinder dimensions and mounting. The magnetic construction also supports reliable sensing in automation environments. These features help with washdown compatibility, regulatory conformity, and system interchangeability.

The glandless spool valve design reduces wear, extending service intervals, while the adjustable cushioning minimizes shock on impact, lowering mechanical wear. Integrated switches and a simplified electrical connection shorten installation time. Claims of up to 50% air consumption reduction compared with conventional systems translate into lower operating costs and faster payback in automated lines.