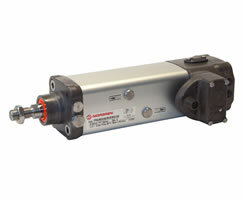

Norgren PRA/882080/MIB/M4/100 IVAC Cleanline Cylinder - IP67

Part Number: PRA/882080/MIB/M4/100

Quick Summary

PRA/882080/MIB/M4/100 IVAC Cleanline cylinder is a precise, high-efficiency actuator for automated assembly lines. In demanding facilities, engineers grapple with wasted compressed air, wear, and downtime that cut productivity. This unit tackles those issues with a glandless spool valve for extended life, adjustable cushioning for smooth starts and stops, and a robust 80 mm bore with 100 mm stroke. It complies with ISO 15552 mounting standards, is IP67-rated, and uses magnetic switches for reliable position sensing. The model also includes Norgren M/50 switches and a single air and electrical connection for quick, clean installations. Together these features reduce energy use, lower maintenance costs, and simplify retrofits, delivering tangible business value in modern manufacturing environments.

Product Information

Extended Description

PRA/882080/MIB/M4/100 Norgren: Cleanline Profile barrel with integrated switches | Glandless spool valve for extended life and high performance | Adjustable flow regulator for speed control | Incorporates Norgren M/50 switches | Single air and electrical connection for quick, simple installation | Cylinders and mountings conform to ISO 15552 (length, mounting pitch and thread dimensions according to ISO 15552. Some outside dimensions different to ISO 15552) | Can potentially reduce air consumption by up to 50% compared to conventional systems

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

2 ... 8 bar, 29 ... 116 psi

Standard

ISO 15552

Port Size

G1/4

Cylinder diameter

80 mm

Stroke Length

100 mm

Operation

Double acting

Valve operation

5/2

Cushioning

Adjustable cushioning

Magnetic/Non-magnetic

Magnetic

Theoretical Force

3016 N

Materials - Barrel

Anodised aluminium

Materials - Piston Rod

Stainless steel

Certification - IP Rating

IP67

Range

PRA/882000

Series

IVAC

Brand

IMI Norgren

C02471038

Pneufit C Push-in fitting, Adaptor, 90° Swivel elbow, 10mm, G3/8

C0K511038

Pneufit C Push-in fitting, Banjo flow control, regulating out, 10mm, G3/8

C02251038

Pneufit C Push-in fitting, Adaptor, Straight, External/Internal hex, 10mm, G3/8

PA2-0010025C

Polyamide tube, Natural, 25m, 10mm/7.5mm

M/3314

Tube cutter

Glandless spool valve design reduces friction, minimizes wear, and extends service life in high-cycle automation such as transfer lines and pick-and-place tasks. This configuration also minimizes air leakage and stabilizes motion, helping maintain consistent cycle times across shifts. In practice, users see lower maintenance interventions and more predictable performance on automation lines. Integrated M/50 switches and a single air and electrical connection streamline wiring and control integration. The result is faster commissioning, simpler field wiring, and reliable sensor feedback to PLCs, reducing installation time by hours on large installations. This setup also supports safe, standardised software integration with existing control modules. Adjustable cushioning provides controlled deceleration, reducing shock to mechanical components and protecting seals during dynamic cycles, improving seal life and reducing vibration-induced wear. ISO 15552 compatibility ensures interchangeable mounting frames and standardised dimensions, enabling straightforward retrofits and replacements without extensive rework. IP67 sealing, an anodised aluminium barrel, and a stainless steel piston rod deliver robustness in dirty or wet environments, with magnetic sensing supporting reliable position feedback. Energy efficiency gains, including potential air consumption reductions up to 50% versus conventional systems, come from precise speed control via the integrated regulator and smoother start/stop sequences. Single air and electrical connection further simplifies installation and maintenance, making upgrades or scale-outs faster and less error-prone.

Get a Quick Quote for a Norgren PRA/882080/MIB/M4/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren PRA/882080/MIB/M4/100?

Enquire Now

FAQs

PRA/882080/MIB/M4/100 is designed for ISO 15552 mounting, using G1/4 ports and an 80 mm bore with 100 mm stroke. It fits standard automation frames and can replace similar ISO 15552 cylinders without extensive rework. Ensure alignment with existing manifolds, verify supply pressure of 2–8 bar, and connect the single air line and electrical lead to the integrated M/50 switches for reliable sensor feedback.

The cylinder is double-acting with a 5/2 valve operation, 80 mm bore, 100 mm stroke, and a theoretical force of 3016 N. With adjustable cushioning and a flow regulator, operators can fine-tune acceleration and deceleration to optimize cycle times. Operating pressure ranges from 2 to 8 bar, enabling fast, repeatable actuation for high-throughput lines while minimizing overshoot and vibration.

Yes. The unit features IP67 sealing, an anodised aluminium barrel, and a stainless steel piston rod, delivering robust protection against dust, water ingress, and corrosion. Magnetic position sensing supports reliable operation in dirty environments, reducing downtime due to misalignment or sensor failure.

The cylinder ships with Norgren M/50 magnetic switches and a single air plus electrical connection, simplifying wiring and reducing cabling errors. This design shortens commissioning time, streamlines diagnostics, and makes field replacements easier, improving overall maintenance efficiency on complex automation cells.

Key benefits include up to 50% reduction in air consumption versus conventional systems, smoother cycle times due to adjustable cushioning, and lower wear because of the glandless spool valve. These factors translate to lower energy costs, reduced maintenance intervals, less downtime, and faster changeovers—critical for high-volume production lines and scalable automation projects.