Norgren PU310800628 Pneuflex Spring Coil - R1/4

Part Number: PU310800628

Quick Summary

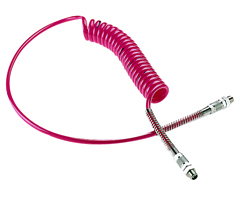

Norgren PU310800628 Pneuflex spring coil provides flexible compressed air lines for automation systems. Engineers frequently confront hose kinks, limited space, and routing headaches on crowded production floors. Certification considerations for pneumatic accessories typically include CE compliance and IP-rated protection; verify these details against the official datasheet. This red 6 m coil is designed in Germany and pairs with 8 mm outer diameter tubing and R1/4 threads, enabling quick, secure installation in compact layouts. By simplifying routing and reducing leak paths, it helps lower maintenance costs and boost uptime. The product aligns with IMI Norgren's standards for durability, performance, and compatibility across a range of pneumatic assemblies.

Product Information

Medium

Compressed air

Colour

Red

Length

6 m

O/D Tube

8 mm

Thread

R1/4

Dimensions - Height

8 mm

Dimensions - Length

6000 mm

Dimensions - Width

8 mm

Weight

0.402 kg

Country of Origin

Germany

Range

PU3

Brand

IMI Norgren

Feature: 6 m spring coil length allows longer, snag-free runs without multiple joints. Impact: Reduces installation time and leak points, lowering maintenance costs. Application: Ideal for automation lines and robotic workcells where space is limited and reliable air supply is critical. Feature: 8 mm outer diameter minimizes bulk while maintaining robust airflow. Impact: Enables compact routing in control panels and machine frames. Application: CNC machines and packaging lines requiring neat, predictable pneumatic layouts. Feature: R1/4 thread compatibility simplifies integration with standard fittings. Impact: Accelerates commissioning and reduces configuration errors. Application: Custom pneumatic assemblies across conveyor systems and automation equipment. Feature: Red color enhances visibility for quick inspections and fault detection. Impact: Improves maintenance efficiency and safety checks in busy environments. Application: Factory floors with dense hose networks. Feature: German engineering quality underpins long-term reliability. Impact: Extends service life, lowers total cost of ownership, and supports compliance. Application: Heavy-use automation lines and industrial machinery with stringent uptime goals.

Get a Quick Quote for a Norgren PU310800628

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren PU310800628?

Enquire Now

FAQs

PU310800628 is designed with an 8 mm outer diameter and an R1/4 thread, making it compatible with standard pneumatic fittings used on Norgren and IMI Norgren systems. It is intended for 6 m lengths of compressed air tubing, and the red color aids in quick visual identification for ongoing maintenance. For exact coupling compatibility with your existing manifolds and fittings, refer to the official datasheet and the nearby 8 mm tube fittings inventory.

The provided data set does not list explicit pressure or temperature ratings. PU310800628 is a pneumatic hose assembly designed for compressed air, with 6 m length, 8 mm OD, and R1/4 thread. To confirm maximum operating pressure and temperature ranges, please consult the Datasheet (PDF) linked in the downloads section or contact the manufacturer directly for the most accurate specifications.

Environmental suitability such as cleanroom compatibility or hazardous-area ratings are not specified in the current data. To determine applicability in such environments, verify the product’s IP rating and material certifications in the official datasheet and ensure alignment with your facility’s safety and cleanliness requirements.

A 6 m length reduces the number of joints and fittings needed, minimizing potential leak points and assembly time. The 8 mm OD maintains a compact profile for routing through tight spaces near robotics and conveyors. Together, these features simplify commissioning and improve system reliability in automation, packaging lines, and CNC environments.

The coil’s spring design supports flexible routing with fewer kink points, reducing wear and the need for frequent replacements. This can translate to lower maintenance labor, reduced downtime, and extended service life for pneumatic circuits in manufacturing and logistics operations. For explicit ROI calculations, compare installation time, leak repair costs, and expected lifecycle against your current hose assemblies.