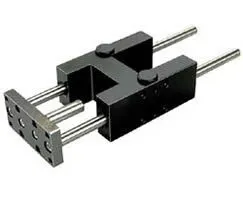

Norgren QA/8032/51/100 Guide Block - 32 mm bore, 100 mm stroke

Part Number: QA/8032/51/100

Quick Summary

The QA/8032/51/100 guide block delivers precise linear motion for compact pneumatic systems in automation lines. Engineers often struggle with wear in plain bearings and misalignment that elevate cycle times and maintenance costs. Certifications and compliance are critical in safety‑critical applications; verify CE marking and IP ratings as applicable to your environment, and confirm SIL reliability where safety interlocks are used. This data highlights a 32 mm bore and 100 mm stroke, reinforcing IMI Norgren’s reputation for reliability, compatibility with standard fittings, and access to installation resources. By choosing this unit, you gain predictable performance, easier integration with existing manifolds, and a clear path to reduced downtime in factory automation and motion‑control workflows.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

The 32 mm bore and 100 mm stroke create a compact pneumatic actuator that fits tight spaces while delivering repeatable travel and predictable motion profiles for automated lines, increasing throughput and reducing misalignment errors. This translates to improved cycle times and lower wear rates over extended production runs, especially in pick-and-place and assembly tasks. The plain bearing style of the guide block minimizes friction and scrolls into smoother operation under variable loads, which lowers maintenance intervals and supports longer service life in busy production environments. Availability of CAD models and an installation guide accelerates engineering validation, helping design teams avoid costly late-stage changes and enabling faster time-to-value for automation projects. The brand’s tested compatibility with standard fittings and mounting interfaces further reduces integration risk and post-install adjustments in retrofits and new lines alike. Industry-ready features support regulatory compliance and predictable performance without sacrificing ease of use for technicians on the shop floor.

Get a Quick Quote for a Norgren QA/8032/51/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/51/100?

Enquire Now

FAQs

Mounting the QA/8032/51/100 uses standard 32 mm bore actuator mounting interfaces and compatible end caps. Begin by aligning the guide block with the mounting surface to prevent binding, then secure with the appropriate bolts per your manifold pattern. Use the provided CAD model to verify clearances and ensure collision-free integration. Always consult the Installation Guide for torque specifications and lubrication recommendations to maintain optimal life of the plain bearings.

Key specs are a 32 mm cylinder bore and a 100 mm stroke, configuring a compact actuator for precise travel. The plain bearing design reduces sliding friction and supports smooth motion, which helps minimize wear under normal load conditions and consistent cycling. For high-duty cycles, ensure proper lubrication and schedule preventive maintenance to sustain repeatable positioning and prevent play that can degrade accuracy.

Yes, its compact 32 mm bore and 100 mm stroke make it suitable for space-constrained pick-and-place and packaging applications. The unit provides predictable travel, smooth motion, and compatibility with standard fittings, aiding quick line integration. For high-speed packaging, validate stroke timing and acceleration against your cycle rates and consider mounting orientation to optimize feed alignment.

Certification details are not listed in the provided data. To ensure compliance for your environment, consult the official Norgren datasheet or contact the supplier for CE marking, IP ratings, and SIL/PL considerations relevant to your safety systems. Always document the exact standards applicable to your installation and verify before deployment in regulated facilities.

Leverage the plain bearing design and reduced friction to extend service intervals, lowering downtime. Factor in lower wear rates, faster assembly validation using CAD resources, and quicker line integration to estimate payback. Compare predicted maintenance costs with current cannibalized spare parts and unscheduled downtime to determine the total cost of ownership benefits over the planned production horizon.