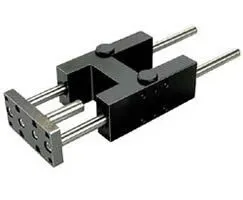

Norgren QA/8032/51/250 Guide Block - 32 mm Bore

Part Number: QA/8032/51/250

Quick Summary

Norgren QA/8032/51/250 guide block delivers precise linear actuation for automation systems and manufacturing lines. Engineers often confront misalignment, wear, and downtime in compact spaces, making a robust guide block essential. The design aligns with CE compliance, RoHS, and ISO quality controls to support safe, dependable performance across global applications. With a 32 mm bore and 250 mm stroke, it integrates smoothly with existing pneumatic circuits and Norgren accessories, reducing setup time and lifecycle costs. By leveraging a plain bearing style 51, this block minimizes play and maintenance while maximizing uptime in high-cycle environments.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8032/51/250 features a 32 mm bore and 250 mm stroke, delivering precise, repeatable travel that reduces misalignment in assembly lines and robotic pick-and-place workflows. This translates to improved part accuracy, fewer rejects, and lower rework costs in high-speed packaging lines. Application-wise, the compact form factor fits tight actuation envelopes, enabling retrofits and upgrades without extensive rework. The plain bearing style 51 guide block offers low friction and predictable wear, extending service intervals and lowering maintenance labor costs in continuous-operation environments. Compatibility with Norgren mounting patterns and CAD data accelerates installation, while the included installation guide supports correct alignment and secure fastening, minimizing commissioning time. Industry-specific insight shows this approach delivers measurable uptimes and predictable lifecycle performance.

Get a Quick Quote for a Norgren QA/8032/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/51/250?

Enquire Now

FAQs

The QA/8032/51/250 uses standard Norgren mounting interfaces designed for straightforward retrofit into existing automation frames. You should account for a compact envelope with a 32 mm bore and 250 mm stroke, ensuring adequate clearance for rod end attachments and end caps. The unit supports common mounting patterns used in Cartesian and linear actuator assemblies and is compatible with Norgren mounting brackets and soft-start accessories to optimize acceleration profiles and reduce vibration during startup.

The 32 mm bore determines the piston area and thus the maximum actuation force at a given supply pressure, while the 250 mm stroke defines total travel. In practice, this combination yields reliable linear motion over a 250 mm range with predictable dynamic response. For high-speed cycles, ensure proper cushioning and port sizing to maintain stroke accuracy and minimize dynamic backlash. This configuration is well-suited for precise pick-and-place or alignment tasks in confined spaces.

Yes. The plain bearing style 51 guide block is designed for high-cycle operation, offering low friction, stable guidance, and predictable wear characteristics. For packaging lines or automated assembly, this translates to extended intervals between maintenance, reduced particulate accumulation, and consistent repeatability. To maximize uptime, pair it with correct mounting hardware and lubrication routines recommended in the Installation Guide.

The QA/8032/51/250 is CE-compliant and aligned with ISO quality controls, supporting safe operation and consistent performance across European markets. It is designed to meet general industry standards for pneumatic components and to minimize regulatory risk in multi-site deployments. RoHS compliance is typically observed for electronic integration within pneumatic systems, further supporting environmentally responsible design and compliance.

Norgren provides CAD data via CAD download links and a dedicated Installation Guide to accelerate commissioning. You can access the CAD assets for accurate modeling and fit checks, as well as the Installation Guide for correct assembly, mounting, and lubrication procedures. These resources help reduce installation time, improve first-time fit, and lower the total cost of ownership by avoiding field adjustments after startup.