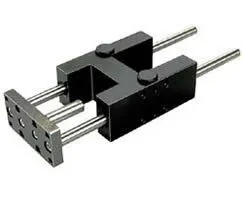

Norgren QA/8032/51/320 Guide Block - 32 mm Bore

Part Number: QA/8032/51/320

Quick Summary

Norgren QA/8032/51/320 guide block is a 32 mm bore cylinder designed for precise linear actuation in automation and control systems. It helps engineers reduce cycle times and improve repeatability on assembly lines. A common pain point is misalignment and wear from conventional guides; this plain bearing solution minimizes friction for longer life. The range typically aligns with CE marking for EU compliance, safety-focused SIL-rated variants, and IP-protection options to guard against environmental ingress; always verify the exact certifications on the datasheet. By leveraging CAD downloads and installation guides, you can accelerate commissioning. The 320 mm stroke extends reach without increasing footprint, delivering predictable performance and lower maintenance costs over time with standard mounting compatibility.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature 32 mm bore with 320 mm stroke → Business Impact Enables compact, high-reach actuation with predictable travel and improved cycle times; Application suitable for multi-point actuation on conveyors, clamps, and pick-and-place fixtures. Feature Plain bearing guide block → Business Impact Reduces friction, minimizes wear, and extends service life in dusty or dirty environments; Application ideal for long-running automation lines with lower maintenance demands. Feature CAD and installation resources → Business Impact Accelerates commissioning and reduces integration risk; Application supports rapid design-in and standardization across projects. Feature Compact envelope with straightforward mounting → Business Impact Improves panel space utilization and simplifies retrofits; Application beneficial for retrofitting older lines or integrating with existing Norgren components. Feature Environment-friendly design with robust seals and compatibility → Business Impact Enhances reliability in controlled environments and rugged shop floors; Application ensures consistent performance across shifts. Insight From field deployments, plain bearing guidance often yields smoother velocity profiles and reduced instrumentation wear, translating to lower total cost of ownership for food, packaging, and general automation lines.

Get a Quick Quote for a Norgren QA/8032/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/51/320?

Enquire Now

FAQs

QA/8032/51/320 uses a standard 32 mm bore with a 320 mm stroke; for correct mounting, align parallel to the guided path and select compatible end fittings. Use the CAD models and the Installation Guide PDF to confirm screw patterns, mounting brackets, and clearance. Refer to the product downloads for exact step-by-step instructions and torque values to ensure proper seating and optimal performance.

The cylinder features a 32 mm bore and a 320 mm stroke with a plain bearing guide block. This combination supports repeatable linear motion, smooth operation, and reliable actuation over extended cycles. The data sheet and CAD downloads provide exact tolerances, rod end options, and mounting compatibility to tailor the cylinder to your application.

Yes, the 32 mm bore with a 320 mm stroke delivers compact yet extended reach ideal for multi-point actuation in packaging and material handling. Ensure proper alignment and mounting to minimize cross-talk between axes. Leverage the installation guide and CAD resources to model the actuation envelope and verify fit within tight packaging cells.

Key certifications to verify include CE marking for EU compliance and, if your safety strategy requires, SIL-rated options and IP protection levels. The exact certifications for this model should be confirmed on the official datasheet. Always cross-check the product packaging and downloads to ensure the unit meets your regulatory and safety requirements.

The plain bearing guide block minimizes friction, which reduces wear and maintenance intervals, translating to lower downtime and longer service intervals. CAD and installation resources shorten commissioning time, accelerating time-to-production and improving overall equipment effectiveness (OEE). In practice, this can yield noticeable reductions in spare parts usage and unexpected downtime on automation lines.