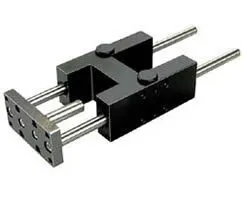

Norgren QA/8032/51/50 Guide Block - 32mm Bore

Part Number: QA/8032/51/50

Quick Summary

Norgren QA/8032/51/50 guide block provides precise linear actuation for compact automation assemblies used in robotics and machine tending. This solution addresses common misalignment and wear in small-bore cylinders by delivering smooth guidance and reliable stroke performance. In addition, many Norgren products align with CE conformity and robust IP-rated sealing where applicable, with SIL readiness achievable through system integration. For engineering teams, the value lies in predictable lifecycle cost, easy installation, and standardized mounting compatibility that reduces downtime. By leveraging the 32 mm bore and 50 mm stroke, manufacturers can optimize footprint without sacrificing force, improving throughput and process repeatability in tight automation cells.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature 32 mm bore and 50 mm stroke delivers consistent piston travel and enhanced control in constrained spaces, improving repeatability and reducing cycle variability in high-speed applications such as pick-and-place. Business impact: tighter process tolerance and fewer quality defects translate to lower scrap and higher throughput in inline assembly lines. Application: ideal for compact pneumatic systems in machine tending cells where stroke reach is critical. Feature Plain bearing guide design minimizes friction and wear, extending service life and reducing maintenance intervals. Business impact: lower lifecycle costs and less unscheduled downtime, supporting continuous production. Application: high-cycle operations in automated handling and packaging lines where reliability matters most. Feature Compact footprint facilitates easier integration into tight machine layouts and robotic cells. Business impact: smaller machine footprints and reduced enclosure complexity lead to installation savings and easier retrofits. Application: upgrading legacy lines or adding new automation modules with limited space. Feature Standard mounting compatibility with common pneumatic manifolds and actuators speeds up installation and part sourcing. Business impact: faster time-to-market and reduced engineering effort during integration. Application: widely adopted in turnkey automation projects and modular lines. Feature Availability of CAD downloads and installation documentation supports fast, error-free integration. Business impact: reduced commissioning time and improved accuracy in line-side deployments. Application: engineering teams deploying QA/8032 series across multiple cells and lines, with confidence in correct fitment and alignment.

Get a Quick Quote for a Norgren QA/8032/51/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/51/50?

Enquire Now

FAQs

QA/8032/51/50 uses standard mounting patterns common to Norgren guide blocks, allowing straightforward integration with compatible manifolds and actuators. When installing, align the bore precisely to ensure smooth rod travel and use the recommended fasteners to avoid misalignment. Reference the Installation Guide for step-by-step torque values and alignment tips to minimize runout and vibration in high-speed cycles.

The unit features a 32 mm bore and a 50 mm stroke, which define piston area and travel distance. The 32 mm bore provides a predictable actuation force suitable for light to medium loads, while the 50 mm stroke offers adequate reach for compact picking and placing tasks. For speed, choose appropriate operating conditions and mounting to minimize parasitic friction and accelerate cycle times.

The guide block is designed for precision actuation in compact pneumatic systems and can be used in pick-and-place applications across various industries. While base performance supports accurate positioning, ensure compatible seals, mounting accuracy, and system integration meet the strict tolerances and cleanliness requirements of aerospace or medical environments. consult the Installation Guide and downstream system designers for qualification steps.

Common industry considerations include CE conformity for European machinery and appropriate IP-rated options depending on application environment. SIL readiness is achievable through system integration and accessory configurations. Always verify the specific certification status for your installation with your supplier and ensure concurrent compliance of the entire automation cell to meet regulatory requirements.

The plain bearing guide and streamlined design reduce wear, lowering maintenance frequency and spare-part costs. The compact footprint simplifies installations and retrofits, cutting installation time and space costs. Over time, predictable cycle life and easier field service translate to lower total cost of ownership and faster return on investment in automated lines.