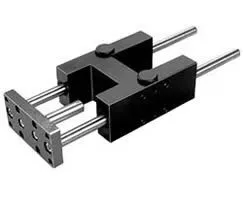

Norgren QA/8032/61/100 - 32 mm Bore, 100 mm Stroke

Part Number: QA/8032/61/100

Quick Summary

QA/8032/61/100 is a precision guide block actuator delivering reliable linear motion for automation and handling tasks. Engineers often wrestle with misalignment, wear, and downtime when selecting bore and stroke combinations that don’t match their machine layouts. In practice, Norgren designs target CE compliance and offer IP-rated and SIL-ready variants to meet safety and environmental requirements. This model’s compact 32 mm bore and 100 mm stroke support tight installations, while CAD resources and installation guides speed integration across automation systems. In today’s competitive environments, choosing a predictable, high-quality actuator reduces engineering time and total cost of ownership for automation projects.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature: 32 mm bore and 100 mm stroke in a guide block roller bearing style actuator. Business Impact: Enables compact yet robust linear motion with consistent accuracy, reducing misalignment and rework. Application: Ideal for tight spaces in packaging lines and machine-tending cells. The 32 mm bore paired with a 100 mm stroke supports versatile reach without sacrificing footprint. Feature: Roller bearing guide reduces friction and wear. Business Impact: Delivers smoother acceleration, longer service life, and reduced maintenance cycles, lowering lifecycle costs. Application: High-cycle automated handling where reliability is paramount. Feature: CAD downloads and Installation Guide available. Business Impact: Speeds design-in and commissioning, shortening time-to-volume production. Application: OEM machine builders and integrators seeking rapid integration. Feature: Compatibility with multiple mounting configurations. Business Impact: Flexible installation options minimize rework and allow retrofits with existing Norgren components. Application: Retrofit projects in existing automation lines. Feature: Compact, lightweight construction. Business Impact: Improves energy efficiency and reduces actuator mass in moving assemblies. Application: Conveyor and pick-and-place applications with limited actuator headroom. Feature: 32 mm bore, 100 mm stroke enable flexible reach in confined spaces. Business Impact: Maximizes deployment options across machines with strict space constraints. Application: Small- to mid-sized automation cells and modular packaging equipment.

Get a Quick Quote for a Norgren QA/8032/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/61/100?

Enquire Now

FAQs

QA/8032/61/100 is designed for seamless integration with Norgren mounting kits and supports CAD downloads via the provided asset links. Designers can quickly verify fit, mounting patterns, and clearances, helping to reduce installation risk and accelerate design cycles.

Begin by inspecting mounting surfaces for alignment, then attach the actuator using the standard mounting options. Connect the supply to the control valve, consult the Installation Guide PDF for air supply ranges and lubrication recommendations, and perform a controlled test to confirm travel and return positioning before production run.

Yes. The 32 mm bore and 100 mm stroke provide adequate reach and compact form for space-constrained pick-and-place setups. The roller bearing guidance delivers smooth, repeatable motion at high cycle rates, aiding precision handling and throughput.

This model is positioned for typical industrial standards, with CE compliance and IP-rated variants commonly available across Norgren’s catalog. Verify specific certification status in the datasheet or contact the supplier for batch-specific documentation and SIL-rated options if safety-critical control is required.

Expect reduced downtime due to low-friction roller guide and longer service life, thanks to robust construction. Regular inspection and adherence to lubrication guidelines from the Installation Guide help maintain performance, contributing to a favorable return on investment through higher uptime and lower maintenance costs.