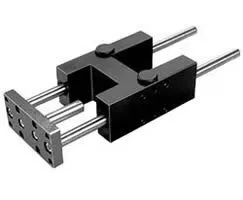

Norgren QA/8032/61/200 Guide Block Roller Bearing Style - 32 mm Bore

Part Number: QA/8032/61/200

Quick Summary

Norgren QA/8032/61/200 guide block roller bearing style delivers precise motion control for compact automation assemblies. When space is limited, engineers struggle to achieve smooth, backlash-free linear motion without sacrificing load capacity. CE marking, IP-rated protection, and SIL compatibility are critical considerations to verify for safety-critical lines. By selecting this model, you gain a compact, reliable actuator option that supports efficient mounting and straightforward maintenance, helping reduce downtime and improve repeatability in OEM equipment. The combination of a 32 mm bore and 200 mm stroke provides a practical balance between force transmission and travel, aligning with broader automation strategies and tighter cycle times.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The QA/8032/61/200 employs a guide block with roller bearing guidance, delivering low friction and high repeatability. This translates to reduced energy consumption, longer service life, and improved positioning accuracy in automated fixtures. Application-wise, it's well-suited for pick-and-place stations in packaging lines and assembly benches where space is at a premium and accuracy is non-negotiable. Feature → Business Impact → Application: A 32 mm bore paired with a 200 mm stroke expands travel while maintaining a compact footprint, enabling more versatile fixture layouts and fewer external extension components. This supports faster line changes and easier retrofits for existing systems in robotics and palletizing setups. Feature → Business Impact → Application: Compatibility with standard Norgren mounting patterns simplifies installation, lowering setup time and calibration effort. In practice, engineers can achieve consistent repeatability across multiple axes, reducing setup variability and commissioning costs. Feature → Business Impact → Application: The roller bearing guidance minimizes wear and noise, delivering predictable performance in continuous operation environments. This reduces maintenance frequency and avoids unexpected downtime in automotive, packaging, and general manufacturing lines. Feature → Business Impact → Application: The design supports straightforward replacement and serviceability, addressing common objections about maintenance complexity. Users benefit from faster part swaps and reduced spare parts inventory, contributing to total cost of ownership reductions in OEM automation projects.

Get a Quick Quote for a Norgren QA/8032/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/61/200?

Enquire Now

FAQs

QA/8032/61/200 utilizes standard Norgren mounting patterns and pre-aligned slots that simplify both panel mounting and rail integration. This enables quick alignment, reduces the need for custom fixturing, and ensures repeatable positioning across multi-axis configurations. For best results, follow the Installation Guide to confirm screw torque, alignment tolerances, and lubrication intervals.

The 32 mm bore provides balanced force transmission with compact dimensions, while the 200 mm stroke delivers extended travel without increasing footprint. In practice, users should expect reliable linear motion with good repeatability, suitable for fixture positioning, simple pick-and-place tasks, and alignment operations in packaging and small automation cells.

The guide block is designed for robust industrial environments, with typical IP-rated protection and sealing suited to factory floors. For cleanroom or highly demanding conditions, verify the exact IP rating and material compatibility with your cleanroom standard and ensure any required seals or coatings are specified by the supplier before deployment.

CE compliance is commonly pursued for European applications, and IP ratings or SIL compatibility are important considerations for safety-critical lines. Confirm the exact certifications with the supplier to ensure alignment with your regional regulations, application safety requirements, and system safety integrity level targets.

Maintenance benefits come from low-friction roller guidance and a compact, serviceable design that simplifies part swaps and routine checks. ROI is typically realized through reduced downtime, faster changeovers, and longer service life, especially in high-cycle applications like packaging, assembly, and automation fixtures.