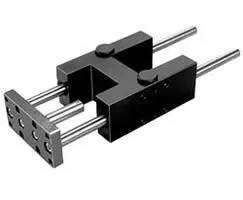

Norgren QA/8032/61/320 Guide block roller bearing style - 320 mm stroke

Part Number: QA/8032/61/320

Quick Summary

Norgren QA/8032/61/320 guide block roller bearing style provides precise pneumatic actuation for linear motion in automation and assembly lines. Engineers often struggle with misalignment and wear in compact automation spaces, leading to downtime and inconsistent motion. This model emphasizes CE compliance and robust IP-rated protection in typical industrial applications, while the 32 mm bore and 320 mm stroke support reliable, repeatable movement. With CAD-ready data and clear installation guidance, it also reduces design time and integration risk, delivering faster time-to-value for robotics, packaging, and material-handling systems.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

32 mm bore with a roller bearing guide delivers precise alignment and high load capacity, minimizing side-load induced wear on the cylinder rod. This design translates to longer service intervals, lower maintenance costs, and more repeatable strokes in automated equipment. The result is improved process stability on 32 mm bore pneumatic cylinder installations used in packaging lines, pick-and-place cells, and small- to mid-sized automation platforms. With a 320 mm stroke, the QA/8032/61/320 enables extended travel between actuators, reducing the number of cylinders needed for longer motions. Operators benefit from simplified pneumatic system architecture and fewer leakage points, which cut setup time and energy consumption. This is particularly advantageous in material handling and assembly processes that require precise end-of-stroke positioning. Backed by the IMI Norgren brand, this actuator benefits from a global support network and readily available spare parts, minimizing downtime. The proven guide block roller bearing arrangement provides smooth motion even in dirty or dusty environments, helping maintain performance without frequent recalibration. Compatibility with standard mounting patterns also simplifies retrofit projects on existing lines. Free CAD download and Installation Guide support rapid integration, reducing engineering cycle times and the risk of misassembly. Having accessible documentation accelerates validation and commissioning, ensuring compliance with internal standards and customer requirements. The combination of robust documentation and a widely used brand helps procurement teams meet project timelines more reliably. In practice, the QA/8032/61/320 delivers measurable ROI through reduced maintenance, energy efficiency, and lower total cost of ownership in high-cycle automation scenarios. Its compact footprint and precise stroke make it a versatile choice for OEMs and system integrators seeking dependable pneumatic actuation without costly redesigns. Additionally, the 32 mm bore equipment aligns with standard compressed air supply levels and minimizes air consumption per cycle, supporting energy-conscious design goals.

Get a Quick Quote for a Norgren QA/8032/61/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/61/320?

Enquire Now

FAQs

The QA/8032/61/320 uses common mounting patterns found in Norgren catalogs and compatible plates. Begin by aligning the bore with the mounting surface, insert spacers as required, and secure with the designated bolts to avoid misalignment. Refer to the Installation Guide for torque specs and load limits to ensure reliable performance in high-cycle applications.

Key specifications include a 32 mm bore for compact yet rigid actuation and a 320 mm stroke for extended travel. This combination supports precise end-of-stroke positioning, consistent repeatability under cyclic loads, and compatibility with standard air supplies and mounting footprints typical in automation and packaging lines.

Yes, the design emphasizes smooth guide-block motion and reliable wear resistance, which are advantageous for high-speed packaging and robotic pick-and-place tasks. The 320 mm stroke supports longer strokes within a compact footprint, reducing the number of actuators required while maintaining cycle accuracy and repeatability.

Typical industrial expectations for this type of actuator include CE compliance and appropriate IP protection levels. Always verify the latest datasheet and installation documentation from Norgren for current certification status and any region-specific requirements before procurement or integration.

Install using the CAD data and Installation Guide to ensure correct alignment and mounting, minimizing misalignment-related wear. Schedule regular inspection of rod ends and seals, and maintain a clean, dry compressed air supply to reduce wear and energy consumption. The combination of reliable motion and supported service networks drives lower maintenance and faster mean time between failures.