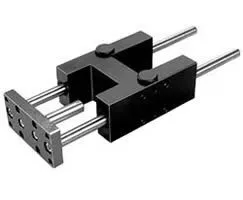

Norgren QA/8032/61/400 Guide Block Roller Bearing Style 61

Part Number: QA/8032/61/400

Quick Summary

QA/8032/61/400 provides precise guide-block roller bearing linear guidance for automated machinery. It helps prevent misalignment and downtime caused by wear, vibration, or uneven loads. In industrial practice, CE safety directives and IP-rated protection are often expected to keep equipment compliant and resilient in harsh environments; for SIL-rated controls, verify requirements with the system designer. The compact design with a 32 mm bore and 400 mm stroke integrates smoothly with Norgren actuation and standard automation kits, supporting easier installation and interchangeability. Access to CAD data and the installation guide streamlines integration, reduces engineering time, and supports predictable maintenance cycles, delivering real business value through reliable motion control.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 32 mm bore and 400 mm stroke provide precise, repeatable travel for compact linear guidance in automation assemblies, reducing end-of-travel errors and increasing part-to-part consistency on small- to mid-sized equipment. This translates to higher throughput and lower reject rates in packaging or assembly lines where tight tolerances matter. Feature → Business Impact → Application: Roller bearing style 61 delivers low friction, smooth motion with reduced stick-slip, cutting energy consumption and wear over time. In robotics and material handling, this supports faster cycle times and longer service intervals, improving OEE metrics. Feature → Business Impact → Application: Full compatibility with Norgren actuation and standard installation kits enables rapid onboarding and scalable upgrades, minimizing downtime during retrofits. For system integrators, this means faster commissioning and fewer integration headaches. Feature → Business Impact → Application: Availability of CAD downloads and Installation Guide (PDF) accelerates design validation and error-free mounting, lowering engineering risk and improving documentation quality. Feature → Business Impact → Application: The compact profile and robust construction help maintain alignment in harsh environments, reducing maintenance costs and ensuring consistent performance across shifts, which is critical in high-volume manufacturing environments.

Get a Quick Quote for a Norgren QA/8032/61/400

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/61/400?

Enquire Now

FAQs

For installation, ensure proper mounting alignment with your existing frame to maintain straight travel. Use the provided CAD data and the Installation Guide PDF to verify hole patterns, fastener sizes, and orientation. Confirm 32 mm bore alignment with the rail surface, and pre-check loads to avoid binding at start-up.

Yes. The QA/8032/61/400 is designed to integrate with Norgren actuation components and standard automation kits. Its 32 mm bore and 400 mm stroke make it a suitable partner for compact pneumatic systems, enabling quick cross-compatibility within a cohesive Norgren installation framework.

Expect a 32 mm cylinder diameter for compact footprint and a 400 mm travel stroke for extended linear reach. The roller bearing style 61 design aims to reduce friction, improving motion smoothness and repeatability while supporting reliable positioning across typical automation tasks in packaging, picking, and handling.

CE safety compliance and IP-rated protection are commonly expected in automation components; verify CE conformity and applicable protection ratings with your supplier. For SIL-related control systems, confirm requirements with your system designer and review the installation documentation for compatibility and safety considerations.

The design emphasizes low friction and robust construction, which reduces wear and downtime, delivering higher uptime and predictable maintenance intervals. Access to CAD data and installation guides speeds up commissioning, lowers design risk, and shortens time-to-value on new lines or retrofits, improving overall return on investment.