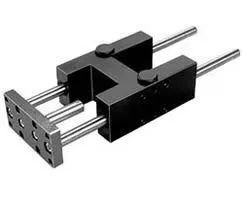

Norgren QA/8032/61/500 Guide Block - 32 mm Bore

Part Number: QA/8032/61/500

Quick Summary

Norgren QA/8032/61/500 guide block delivers precise 32 mm bore linear motion for automation. Engineers often struggle with misalignment and wear in long-stroke cylinders, driving downtime and maintenance costs. This design aligns with CE safety expectations and IP-rated rugged environments, while SIL considerations may apply in control-system design. With readily available CAD data and an Installation Guide, commissioning is faster, installation accuracy improves, and lifecycle costs are reduced. Compact 32 mm bore and 500 mm stroke enable space-efficient integration in automation lines, while the IMI Norgren heritage supports seamless sourcing and maintenance.

Product Information

Cylinder diameter

32 mm

Brand

IMI Norgren

Feature: 32 mm bore and 500 mm stroke provide robust travel with a compact footprint. Business Impact: Enables longer reach per actuator and fewer devices in a single line, boosting throughput while maintaining precision in pick-and-place tasks. Application: Conveyors and machine-tending cells where space constraints exist and repeatable positioning is critical. Long-tail keyword integration: 32 mm bore pneumatic cylinder, 500 mm stroke, guide block roller bearing style 61. Feature: Roller bearing style reduces play and backlash. Business Impact: Improves repeatability and reduces maintenance downtime, lowering total cost of ownership. Application: High-precision positioning in automated assembly and packaging lines. Long-tail keyword integration: roller bearing guide blocks, precision motion components. Feature: CAD data and Installation Guide availability. Business Impact: Accelerates design-in and commissioning, reducing engineering hours and mistakes. Application: New line build-outs and retrofits in automation & control systems. Long-tail keyword integration: CAD download, installation guide pdf, Norgren compatibility. Feature: IMI Norgren branding ensures compatibility with existing equipment and service networks. Business Impact: Simplifies spare parts planning and supplier alignment, reducing downtime. Application: Integrated systems with standard Norgren components. Long-tail keyword integration: IMI Norgren compatibility, spare parts planning. Feature: 32 mm bore, 500 mm stroke balance compactness with travel. Business Impact: Supports compact layouts without sacrificing stroke requirements, improving line density. Application: Robotics cells and automated transfer lines. Long-tail keyword integration: compact pneumatic cylinder, automation line density.

Get a Quick Quote for a Norgren QA/8032/61/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8032/61/500?

Enquire Now

FAQs

The QA/8032/61/500 is designed for straightforward integration with typical Norgren mounting patterns. Begin by aligning the guide block with the bore rail, secure with compatible bolts, and verify straight-line travel. Use the CAD data to confirm footprint and mounting hole locations, then consult the Installation Guide pdf for step-by-step torque specs and alignment tips to ensure optimal performance.

Key specs include a 32 mm cylinder diameter (bore) and a 500 mm stroke, configured in a roller bearing style 61. The combination reduces backlash, enhances repeatability, and supports longer travel between actuators without sacrificing precision. These attributes directly improve positioning accuracy in pick-and-place and material-handling tasks.

Yes, the 32 mm bore with a 500 mm stroke provides a compact yet capable solution for high-speed packaging setups. The roller bearing style minimizes play, promoting consistent cycle times and reduced cycle-to-cycle variation. For peak throughput, ensure proper mounting, lubrication, and alignment as outlined in the Installation Guide.

No explicit certifications are listed in the provided data. Typical automation components consider CE safety compliance and IP ratings, with SIL considerations in control-system design. Always verify the exact certifications in the official datasheet or installation documents before regulatory use in a given environment.

The roller bearing design reduces backlash and wear, leading to longer service intervals and lower maintenance costs. Faster commissioning from CAD data and guides shortens project timelines, while improved repeatability translates to higher first-pass yield and reduced scrap. Over time, these factors contribute to a favorable return on investment in automated lines.