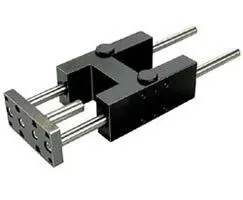

Norgren QA/8040/51/100 Guide Block - 40 mm Bore

Part Number: QA/8040/51/100

Quick Summary

QA/8040/51/100 guide block is a precision linear actuator designed for reliable motion control in automated assembly lines. Misalignment, debris, or flexible mounting can trigger wear and downtime, undermining throughput. Key specs such as 40 mm bore and 100 mm stroke support compact packaging and predictable stroke performance. When selecting pneumatic guides, engineers typically verify CE compliance, IP ratings for protection, and SIL considerations for safety-critical applications. This Norgren solution offers CAD integration, compatibility with related guide blocks, and a path to reduced total cost of ownership. Used in automation tasks from pick-and-place to tooling alignment, it delivers repeatable motion and long service life.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: 40 mm bore and 100 mm stroke in a plain bearing guide block provide compact, reliable linear motion suitable for tight machine envelopes. Business impact: this combination enables precise travel with consistent repeatability across high-cycle production, reducing rework caused by misalignment and backlash. Application: ideal for small-form automation tasks such as pick-and-place, label application, and packaging line indexing, where space is at a premium and uptime is critical. Feature: plain bearing design reduces friction, wear, and lubrication demands compared with traditional bushings. Business impact: lower maintenance intervals, longer service life, and lower total cost of ownership in continuous operation environments. Application: well-suited for high-cycle automation on assembly lines, fed-belt systems, and tooling stations where rapid, repeated actuation is required. Feature: compatibility with Norgren accessories and standard mounting interfaces enables flexible system design. Business impact: simplifies retrofits and new builds by reducing custom hardware, speeding up commissioning, and ensuring consistent performance across a production line. Application: plug-and-play integration in automated machines, robotics tooling, and pneumatic distribution blocks. Feature: CAD downloads and Installation Guide PDF availability streamline design-in and installation. Business impact: speeds design-in, minimizes integration errors, and reduces on-site commissioning time. Application: OEM machine builders and systems integrators leveraging CAD workflows to accelerate project timelines. Feature: IMI Norgren legacy and spare-part support provide long-term reliability. Business impact: predictable maintenance planning, reduced downtime, and improved asset uptime across manufacturing operations. Application: industrial automation and process control environments requiring dependable pneumatic guidance.

Get a Quick Quote for a Norgren QA/8040/51/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/100?

Enquire Now

FAQs

To install, verify bore and stroke match your design, align mounting holes to the standard pattern, and follow the Installation Guide PDF. Use the CAD models to validate fit before assembly and ensure correct torque on mounting fasteners. The block is designed to integrate with Norgren accessories and common pneumatic distribution hardware for streamlined commissioning.

Expect repeatable travel with minimal backlash due to the plain bearing design, even under rapid cycling. The 40 mm bore keeps the assembly compact while the 100 mm stroke provides sufficient reach for common packaging tasks. Proper lubrication and environment control are still recommended to maximize life and minimize wear in continuous operations.

Yes. The compact bore and stroke fit tight work envelopes typical of robotics tooling, and the unit is compatible with Norgren mounting interfaces and accessories. Its predictable motion, plus available CAD models and installation guides, supports quick design-in and reliable performance on pick-and-place stations and tooling alignment tasks.

Check for CE marking to confirm European compliance, IP ratings appropriate to your environment, and SIL considerations if the application involves safety-critical operation. While the specific data sheet here may not list every certification, these are common requirements for pneumatic guide blocks in industrial automation; always review the datasheet and installation guide for exact certifications.

The plain bearing design reduces friction and wear, lowering lubrication frequency and extending service life, which translates to longer maintenance intervals and higher uptime. A compact form factor lowers installation costs and speeds integration with existing lines, improving overall asset utilization and return on investment in manufacturing environments.