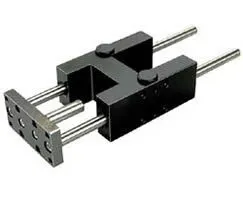

Norgren QA/8040/51/160 Guide block plain bearing cylinder - 40 mm Bore

Part Number: QA/8040/51/160

Quick Summary

The Norgren QA/8040/51/160 guide block plain bearing cylinder delivers precise linear actuation for compact automation in packaging, assembly, and fixture applications. Space constraints, long installation times, and misalignment are common pain points engineers face when integrating actuators into tight machine layouts. Where applicable, CE compliance, IP-rated ruggedness, and SIL-ready control compatibility are critical for safe, reliable operations in European and global facilities. With a 40 mm bore and a 160 mm stroke, this actuator minimizes footprint while maximizing travel, enabling faster line changeovers and predictable maintenance. CAD assets and an Installation Guide streamline design-in and commissioning, helping teams shorten project timelines and lower total cost of ownership.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature → Business Impact → Application: The 40 mm bore delivers a compact footprint that reduces enclosure space and material costs, while maintaining sufficient force for small- to mid-size pick-and-place tasks; this translates to shorter machine footprints and lower overall system weight. Application: ideal for tight-pack automation lines and component handling where every millimeter of space matters. Feature → Business Impact → Application: A 160 mm stroke extends travel within a minimal frame, decreasing the number of actuators and mountings required and enabling longer travel in tight layouts; benefit: fewer assembly steps and faster changeovers. Application: suitable for fixture actuation, automated clamping, and return-to-home cycles in packaging and assembly cells. Feature → Business Impact → Application: Guide block plain bearing style 51 provides low friction, smooth guidance, and robust long-cycle performance, reducing energy consumption and maintenance intervals; value: predictable motion and lower operating costs. Application: high-cycle positioning and alignment tasks in automotive, electronics, and general industrial automation. Feature → Business Impact → Application: CAD-ready downloads and installation guides accelerate design-in, mitigate commissioning risk, and shorten project timelines; value: faster prototyping and reduced engineering overhead. Application: engineering teams integrating this cylinder into multi-axis systems. Feature → Business Impact → Application: Norgren lineage and compatibility with standard components enhance supply chain resilience and aftermarket support; value: easier spare parts planning and consistent performance across lines. Application: retrofits and expansions of existing automation platforms.

Get a Quick Quote for a Norgren QA/8040/51/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/160?

Enquire Now

FAQs

The QA/8040/51/160 uses a compact 40 mm bore and standard linear actuator footprint designed to align with common mounting patterns used in compact automation cells. It supports straightforward alignment with minimal shims, and the CAD download helps engineers verify hole spacing and connection points before procurement. When mounting, confirm compatibility with your end-effector and fixture design to ensure robust repeatability.

Key specifications include a 40 mm bore and a 160 mm stroke, along with the guide block plain bearing configuration for smooth, low-friction motion. While material and weight data are not listed here, the configuration is optimized for compact actuation with reliable long-cycle performance in automated lines. For precise tolerances and installation limits, consult the Installation Guide.

Best-suited applications include compact pick-and-place, fixture actuation, clamping, and short-stroke motion control in packaging, electronics assembly, and small-component handling. The 160 mm travel supports longer reach within tight spaces, while the 40 mm bore keeps the assembly lightweight and easy to integrate with existing tooling and grippers.

Industry practice for automation actuators often includes CE marking for European compliance, and IP ratings for environmental protection. For SIL readiness and other safety certifications, verify with the distributor and review the installation documentation to ensure your system’s safety and risk mitigation requirements are met in your facility.

The plain bearing guide design reduces friction, contributing to smoother motion and longer service intervals, which lowers maintenance costs and downtime. Availability of CAD assets and a dedicated installation guide accelerates commissioning, shortening project timelines and delivering faster time-to-value for automation upgrades and retrofits.