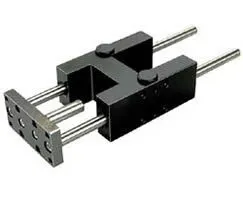

Norgren QA/8040/51/200 Guide block plain bearing style - 40 mm bore, 200 mm stroke

Part Number: QA/8040/51/200

Quick Summary

Norgren QA/8040/51/200 is a guide block plain bearing pneumatic cylinder delivering precise linear actuation for automation and control applications. Operators and engineers frequently contend with misalignment, wear, and downtime from long-stroke guides that erode cycle times and inflate maintenance costs. While the data sheet does not list SIL, CE, or IP ratings, consult Norgren documentation for certification details and ensure alignment with your facility's compliance requirements. Designed for easy integration, it supports standard mounting patterns and provides CAD resources and an installation guide to speed engineering, reduce design risk, and improve overall equipment effectiveness. By standardising on a compact 40 mm bore and 200 mm stroke, teams can simplify parts inventories and maintenance scheduling, delivering predictable performance across automated lines. This combination helps lower total cost of ownership and supports scalable plant modernization.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: The 40 mm bore and 200 mm stroke deliver compact, capable linear actuation. In practice, this geometry yields repeatable strokes and efficient motion for automation cells and packaging lines. Business Impact: Improved cycle consistency and reduced intervention translate to higher throughput and lower labor costs. Application: Suitable for small-to-mid load tasks in automation and control environments. Feature: Plain bearing guide reduces friction and wear for smoother motion. Business Impact: Lower maintenance costs and longer cycle life in high-cycle applications such as pick-and-place and material handling. Application: Robotics-assisted assembly and packaging lines benefit from reliable, low-friction operation. Feature: CAD compatibility and an Installation Guide provide engineering-ready resources. Business Impact: Faster commissioning, fewer mounting errors, and smoother system integration for retrofits. Application: System integration projects and line expansions across manufacturing cells. Feature: Strong brand reliability with access to Norgren spare parts and support within the IMI portfolio. Business Impact: Consistent performance, easier sourcing, and reduced downtime across multi-site plants. Application: Plant-wide modernization and maintenance planning. Feature: Compatibility with standard mounting patterns and accessories simplifies installation. Business Impact: Reduced commissioning time and easier expansion of automated cells. Application: Multi-axis lines and modular automation setups.

Get a Quick Quote for a Norgren QA/8040/51/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/200?

Enquire Now

FAQs

QA/8040/51/200 uses common mounting interfaces typical for Norgren precision cylinders, including standard flange patterns compatible with many ISO mounting kits. Check the Installation Guide and CAD files to confirm hole spacing, alignment tolerances, and accessory fitment. If retrofitting into an existing line, verify bore alignment, stroke consistency, and available end-cap options for seamless integration.

Performance depends on supply pressure and load profile. The 40 mm bore provides a reasonable actuation area (and thus force per pressure unit), while the 200 mm stroke supports longer travel within a compact footprint. For rough estimates, use F = P × A to determine push/pull force, and select a drive speed that preserves smooth motion from the plain bearing guide to minimize wear.

The product data here does not list explicit IP ratings or SIL/CE certifications. For environmental and regulatory compatibility, consult the official Norgren documentation and the Installation Guide. If IP protection or safety certifications are required for your application, consider enclosure solutions or alternative, certified variants within the Norgren portfolio.

Plain bearing guides benefit from periodic inspection and lubrication per the Installation Guide. Check for unusual wear, ensure alignment is preserved by proper mounting, and schedule lubrication in line with cycle frequency. Proper lubrication and clean installation help maintain smooth motion and extend the life of the guide rails in high-cycle environments.

The cylinder’s compact form factor and smooth plain bearing motion reduce cycle times and downtime, while CAD-friendly resources speed engineering and commissioning. Its compatibility with standard accessories simplifies maintenance and spares planning, contributing to lower total cost of ownership and faster payback in high-volume packaging and material handling lines.