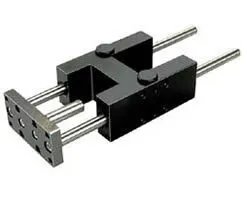

Norgren QA/8040/51/250 Guide Block - 40 mm Bore

Part Number: QA/8040/51/250

Quick Summary

QA/8040/51/250 guide block provides precise linear guidance for pneumatic actuators in automation systems. Engineers often confront wear, misalignment, and downtime when using plain bearing blocks, which disrupts production and increases maintenance costs. In industrial practice, CE marking and IP-rated protections are common expectations for automation components, with SIL considerations typically addressed at system level. This model aligns with those expectations by emphasizing reliability and ease of integration. By leveraging this guide block alongside standard 40 mm bore cylinders, OEMs and maintenance teams gain predictable performance, simplified stocking, and faster installation, delivering tangible business value in high-volume manufacturing environments.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: 40 mm bore with 250 mm stroke and plain bearing style. Business impact: delivers consistent guidance with reduced play, improving repeatability and component life. Application: ideal for high-precision linear motion in automation and control systems. In practice, users see lower maintenance costs and less downtime on conveyance and pick-and-place lines. Feature: Compatibility with standard 40 mm bore cylinders. Business impact: simplifies integration, minimizes engineering time, and speeds active line commissioning. Application: retrofit projects and new builds across packaging and assembly applications. Feature: CAD availability and Installation Guide access. Business impact: accelerates design verification, reduces mounting errors, and supports compliant installations. Application: engineering validation and field servicing. Feature: Maintenance-friendly plain bearing design. Business impact: lower friction, longer life, easier lubrication intervals, and lower total cost of ownership. Application: high-cycle automation systems. Feature: Compact, lightweight form factor with stable alignment. Business impact: ease of handling, reduced mounts, and improved energy efficiency. Application: space-constrained automation setups and mobile production lines.

Get a Quick Quote for a Norgren QA/8040/51/250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/250?

Enquire Now

FAQs

Begin by reviewing the installation guide and CAD files. Align the guide block with the cylinder mounting surface, insert alignment dowels if present, secure with standard 4-40 or M4 mounting holes, then verify straight-line travel using the 40 mm bore alignment reference. Lubricate per the guide’s recommendations and cycle-test the assembly to confirm smooth movement before full production use.

Key specs include a 40 mm bore, a 250 mm stroke, and a plain bearing style designed for reliable linear guidance. The product is branded IMI Norgren, with compatibility to standard 40 mm bore pneumatic cylinders and corresponding mounting hardware. The CAD and installation documentation are provided to support accurate integration.

Yes. The 40 mm bore and 250 mm stroke configuration supports typical packaging line movements, offering repeatable alignment and robust guidance for pick-and-place and transfer stages. The plain bearing design helps reduce friction and wear in high-cycle environments, while CAD resources simplify reuse in multiple packaging formats.

The provided data does not list specific certifications. For European deployments, CE compatibility is commonly expected in automation components, and IP ratings are typically determined by the enclosure and installation environment. Refer to the Installation Guide and supplier communications to confirm exact regulatory and protection standards for your use case.

The plain bearing design reduces friction and wear, contributing to longer service intervals and lower replacement costs. Availability of CAD and installation guides streamlines setup and reduces commissioning time, improving overall equipment uptime and return-on-investment for automation projects.