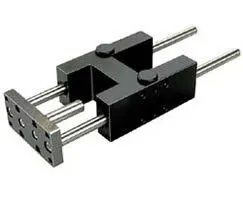

Norgren QA/8040/51/320 Guide Block 40 mm bore, 320 mm stroke

Part Number: QA/8040/51/320

Quick Summary

QA/8040/51/320 guide block provides precise linear guidance for automation and motion control in packaging and assembly. Engineers often battle misalignment, wear, and downtime when long-stroke actuators push systems to the edge. Designed with CE-compliant safety and robust IP-rated protection, it maintains performance in dusty or damp factory floors. Choosing a standardized 40 mm bore and 320 mm travel reduces spare-parts variety and accelerates installation, translating to lower total cost of ownership and faster time-to-value for automation projects. This alignment with Norgren's precision standards helps equipment builders meet tight cycle times while maintaining reliability across diverse production environments.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: The guide block uses a plain bearing style 51 with a 40 mm bore to deliver low-friction travel and stable guidance. Business Impact: This reduces wear, extends service life, and lowers maintenance costs on high-cycle axes. Application: Ideal for automated assembly stations, conveyors, and packaging lines that demand repeatable positioning. Feature: Extended 320 mm stroke provides substantial travel within a compact footprint. Business Impact: Fewer actuator swaps and fewer mechanical stops, enabling longer reach in a single cylinder. Application: Material handling, high-mix packaging, and pick-and-place tasks where stroke length matters. Feature: CAD and Installation Guide downloads streamline engineering workflows. Business Impact: Reduces design time, standardizes mounting patterns, and accelerates commissioning. Application: Design-phase integrations and retrofit projects across automation lines. Feature: Brand compatibility and standard mounting patterns with Norgren accessories enhance actionable integration. Business Impact: Simplifies retrofits and spare-parts management, improving lifecycle planning and total cost of ownership. Application: Upgrades to aging lines and new line deployments in factories. Feature: Robust design for environmental resilience and safety. Business Impact: Improves uptime in harsh environments and supports compliance with plant safety practices. Application: Industrial automation across automotive, electronics, and food & beverage sectors.

Get a Quick Quote for a Norgren QA/8040/51/320

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/320?

Enquire Now

FAQs

To install the QA/8040/51/320, align the block with the mounting plates and rail system using the standard bolt patterns. Use the CAD download for exact hole spacing and orientation, then tighten to the recommended torque to ensure parallelism and repeatable stroke. Confirm clearances and test travel before full operation.

The module features a 40 mm bore and a 320 mm stroke within a plain bearing guide block style 51. It is designed for stable, low-friction guidance and reliable repeatability in automated motion tasks, supporting consistent positioning in high-cycle applications.

Yes. The combination of 40 mm bore and 320 mm stroke offers precise, repeatable travel suitable for pick-and-place, conveyor transfers, and packaging-line indexing. Its plain bearing guidance minimizes wear, reducing maintenance interruptions and boosting line throughput in repetitive packaging cycles.

The design supports CE safety compliance and robust protection for challenging environments, aligning with typical industrial standards. Verify exact certifications with your procurement team and local regulatory requirements to ensure full conformance for your specific installation.

thanks to the low-friction plain bearing design, maintenance intervals are extended and downtime is reduced. The 320 mm stroke reduces the number of actuators required for longer reaches, delivering lower total cost of ownership over the life of the automation system and faster payback on retrofits.