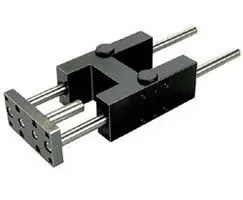

Norgren QA/8040/51/50 Guide Block - 40 mm Bore

Part Number: QA/8040/51/50

Quick Summary

QA/8040/51/50 guide block provides precise 40 mm bore linear actuation for automated assembly lines. Engineers often struggle with misalignment and wear in compact cylinders, which can throttle throughput and drive up maintenance costs. This design supports industry-standard practices, including CE-compliant installations, typical IP-rated enclosures, and SIL-ready options where required. By delivering consistent travel and smooth motion, it minimizes wear and downtime. The solution aligns with common automation and control systems architectures, enabling straightforward integration with existing manifolds, brackets, and CAD models. In short, it combines dependable performance with reduced lifecycle costs, making it a practical choice for OEMs and end users seeking reliable, scalable pneumatic actuation.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: 40 mm bore and 50 mm stroke deliver a compact, high-precision actuation envelope. Business Impact: Enables tight packaging, faster cycle times, and repeatable positioning in automated lines. Application: Robotics fixtures, pick-and-place stations, inline conveyors. Feature: Plain bearing style 51 delivers low friction and smooth travel. Business Impact: Reduces wear, extends service life, and lowers maintenance intervals. Application: High-cycle operations where consistent travel is critical. Feature: Standard mounting interface and compatibility with Norgren accessories. Business Impact: Faster installation, fewer custom brackets, and easier retrofits. Application: OEM line integrations and factory floor upgrades. Feature: Availability of CAD data and Installation Guide. Business Impact: Accelerates commissioning, minimizes alignment errors, and supports trouble-free field setups. Application: New installations and retrofit projects across automation cells. Feature: Compliance considerations with CE and typical IP ratings; SIL-ready options where required. Business Impact: Supports regulatory alignment and safer operation in controlled environments. Application: Regulated manufacturing, packaging, and automotive/industrial environments.

Get a Quick Quote for a Norgren QA/8040/51/50

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/50?

Enquire Now

FAQs

Yes. QA/8040/51/50 uses the standard Norgren mounting interface common to IMI Norgren guide blocks, enabling straightforward integration with existing equipment. Before installation, verify hole spacing and piston alignment. Use the included CAD data and the Installation Guide to confirm connector patterns, ensuring a clean, quick commissioning process in robot cells or packaging lines.

The model features a 40 mm bore and a 50 mm stroke, paired with a plain bearing style 51 configuration for smooth, low-friction travel. This combination supports reliable repeatability in medium-cycle to high-cycle applications. Confirm fits with the CAD resources and installation recommendations to optimize orientation and minimize end-of-stroke impact.

Industries that require compact, precise linear motion benefit from the QA/8040/51/50 design, including automotive assembly, packaging, automation cells, and fixture work. Its 40 mm bore fits tight spaces while the 50 mm stroke provides adequate travel for short-throw actuation. It integrates with standard manifolds and brackets, enabling scalable solutions across multiple production lines.

The Norgren line typically supports CE-compliant installations and standard IP-rated enclosures; SIL-ready options are available for safety-critical lines. Always verify the exact model datasheet and the Installation Guide for your jurisdiction to ensure regulatory compliance and correct safety-rated configuration in your environment.

ROI is driven by reduced wear from the plain bearing design and predictable motion, which lowers maintenance costs and downtime. Quick commissioning is enabled by downloadable CAD data and an installation guide, shortening project timelines. Coupled with reliable performance over time, this reduces spare parts usage and extends mean time between failures in automation and control systems.