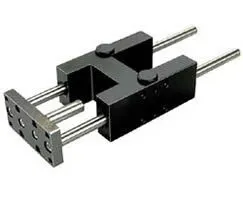

Norgren QA/8040/51/500 Guide block - 40 mm bore

Part Number: QA/8040/51/500

Quick Summary

QA/8040/51/500 guide block provides precise linear motion for automation systems. Many engineers face misalignment, debris ingress, and downtime on long-stroke actuators in tight spaces. This model pairs a 40 mm bore with a 500 mm stroke to deliver repeatable performance, while CE compliance and IP-rated protection are standard considerations in European and rugged environments. Leaning on our CAD resources and installation guides helps shorten commissioning, reduce errors, and streamline supplier integration. Organizations benefit from predictable cycle times, reduced maintenance, and easier retrofits when upgrading to standard-length strokes. This page also highlights downloadable CAD models and an Installation Guide to accelerate setup and ensure compliant installations.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature 40 mm bore and 500 mm stroke deliver balanced actuation for mid-range force and travel, with piston area yielding predictable response across loading. This combination supports consistent velocity profiles and cleaner stroke control in automation cells, packaging lines, and material handling where space is at a premium. Operators appreciate the predictable motion that reduces misalignment risk and simplifies downstream control. Feature Plain bearing guide block design minimizes friction and wear versus sleeve-guided alternatives, extending service life in high-cycle operations. The geometry supports smooth start-stop cycles and stable positioning, improving repeatability on part transfer tasks. In industries such as food packaging and electronics assembly, reduced maintenance translates to higher line uptime and lower lifecycle costs. Feature ISO mounting compatibility and compatibility with Norgren components simplify integration into existing plants. Engineers can leverage the CAD models and the Installation Guide to validate mounting patterns, bracket options, and end-of-stroke cushioning before procurement. This reduces design iterations and helps procurement teams lock in delivery schedules with confidence. Feature Long life and easy maintenance contribute to a lower total cost of ownership, especially in rugged environments. The design tolerances and robust materials withstand exposure to dust and contaminants when paired with proper seals and lubrication. Operators also benefit from faster commissioning and fewer field adjustments after initial installation. Feature CAD downloads and an Installation Guide accelerate setup by providing exact geometries, mounting holes, and connection points. With these resources, technicians can plan wiring, tubing routing, and sensor placements in advance, reducing on-site errors and enabling rapid integration with the control system.

Get a Quick Quote for a Norgren QA/8040/51/500

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/51/500?

Enquire Now

FAQs

QA/8040/51/500 uses common ISO mounting interfaces used in Norgren actuators; verify bore and stroke to ensure bracket fit and clearance. The available CAD file and Installation Guide provide mounting hole locations, pattern references, and end-of-stroke cushioning options to speed alignment and reduce rework during commissioning.

The piston area for a 40 mm bore yields a predictable force range that scales with supply pressure; a 500 mm stroke enables longer travel between end stops. Together, they support stable velocity profiles and consistent positioning in mid-range automation tasks, such as pick-and-place and material handling, when paired with proper air preparation and lubrication.

Industries involving automated assembly, packaging, and material handling benefit most from this model due to its balanced actuation, long travel, and compatibility with standard mounting patterns. Its plain bearing guide block design delivers low maintenance in high-cycle lines, improving uptime in electronics assembly, food packaging, and automotive component fitting.

Check the official datasheet for explicit CE marking and IP protection ratings; verify SIL considerations with your system integrator if safety-critical functions are involved. The Installation Guide and CAD resources often reference these certifications. If in doubt, contact Norgren or your local distributor to confirm current compliance for your region and application.

The long-stroke, low-friction plain bearing design reduces wear and downtime, while CAD downloads shorten setup and validation times. This combination lowers maintenance intervals and accelerates commissioning, contributing to a faster return on investment, especially on high-cycle lines and cells requiring reliable repeatability and quick retrofit capability.