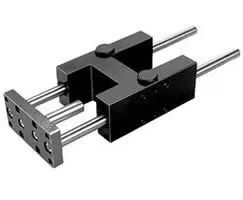

Norgren QA/8040/61/100 Guide Block – 40 mm Bore, 100 mm Stroke

Part Number: QA/8040/61/100

Quick Summary

The QA/8040/61/100 guide block delivers precise linear actuation for automation and control systems across manufacturing environments. Engineers often face misalignment, wear, and downtime, which this roller-block guidance solution helps reduce through stable, smooth travel. This design supports CE directives and is suitable for integration in IP-rated environments, enabling SIL-ready safety configurations when paired with compatible controls. By combining a compact form with robust performance, it delivers meaningful improvements in uptime and lifecycle costs while fitting into existing automation architectures and pneumatic systems.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: Robust guide block roller bearing design → Business Impact: Reduces play and wear, delivering consistent motion and longer life, which lowers maintenance frequency in high-cycle applications. Application: Ideal for high-speed pick-and-place and conveyor-guided assemblies in automotive and electronics manufacturing. Feature: 40 mm bore and 100 mm stroke → Business Impact: Provides precise travel and repeatable positioning for clamping and actuating tasks, improving part quality and cycle accuracy. Application: Suitable for end-of-line tooling and fixture actuation in automated assembly lines. Feature: Compact, lightweight construction → Business Impact: Simplifies installation in tight spaces and reduces overall system weight, enabling easier retrofits and modular upgrades. Application: Retrofit projects and new line designs where space is at a premium. Feature: Direct mounting compatibility and clear installation guidelines → Business Impact: Accelerates commissioning, minimizes misalignment risk, and reduces installation costs. Application: Retrofit into existing Norgren manifolds or standardized ISO mounting patterns. Feature: Seals and lubrication-friendly design → Business Impact: Extends service intervals and lowers total cost of ownership by reducing maintenance and downtime. Application: Continuous operation in harsh environments and automated packaging lines. Feature: Safety-conscious integration options → Business Impact: Supports safer operation within CE-compliant systems and enables safe SIL-capable control architectures when paired with appropriate safety components. Application: Industrial zones requiring regulatory-aligned performance and reliable control logic.

Get a Quick Quote for a Norgren QA/8040/61/100

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/100?

Enquire Now

FAQs

QA/8040/61/100 uses standard guide block mounting interfaces designed for IMI Norgren systems, facilitating straightforward retrofit onto common ISO mounting patterns. When installing, verify bore alignment, confirm mounting hole spacing matches the existing plate, and use appropriate fasteners to ensure rigid coupling. The result is reduced misalignment, smoother travel, and faster commissioning.

The actuator features a 40 mm cylinder diameter and a 100 mm stroke, with a guide block roller bearing design that delivers stable, repeatable linear motion. This configuration supports high-cycle automation, tight positioning tolerance, and predictable acceleration profiles. For specific applications, confirm operating pressure ranges and fitment with your pneumatic supply and valve packages.

The design supports integration into CE-compliant systems and can operate in IP-rated environments when paired with appropriate enclosures and protective coatings. For rigorous safety and environmental requirements, combine the actuator with compliant control panels, conformal seals, and validated safety interlocks to meet regional regulations and your safety management plan.

Begin with verifying the mounting pattern compatibility and cylinder alignment. Install the guide block with properly torqued fasteners, connect the supply lines to the correct porting, and perform a low-speed test to check for smooth travel and absence of binding. Using the provided installation guide reduces commissioning time and minimizes adjustments during initial operation.

Plan for routine inspection of seals, lubrication points, and mounting integrity at defined intervals. The roller-bearing guide reduces wear-induced play, supporting longer service intervals and lower downtime. In typical high-cycle lines, this translates to improved uptime, fewer part replacements, and a faster return on investment through enhanced process reliability.