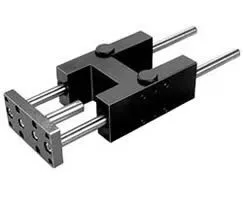

Norgren QA/8040/61/160 Guide Block Roller Bearing Style 40 mm Bore

Part Number: QA/8040/61/160

Quick Summary

The Norgren QA/8040/61/160 guide block roller bearing enables precise linear motion in automated assembly lines. Engineers often grapple with misalignment and stiction when integrating compact cylinders into existing automation, which slows cycles and increases wear. CE marking, IP-rated variants, and SIL-ready options provide safety and reliability in European, harsh-environment, and safety-critical applications. With a 40 mm bore and 160 mm stroke, this unit delivers repeatable performance, while CAD data and installation guides streamline integration and ongoing maintenance for smarter, more efficient production.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: 40 mm bore and 160 mm stroke deliver precise, repeatable motion with a compact footprint. Business impact: Enables faster cycle times and tighter tolerances in packaging, pick-and-place, and transfer applications. Application: Suitable for compact automation cells where space is at a premium and accuracy matters. Feature: Guide block roller bearing style 61 provides smooth, low-friction guidance under load. Business impact: Reduces wear, extends service life, and lowers maintenance costs in high-cycle environments. Application: Ideal for high-volume conveyor and tooling stations with repetitive directional changes. Feature: Compatibility with standard mounting patterns and downloadable CAD data speeds integration. Business impact: Shortens engineering lead times and reduces design risk, improving ROI. Application: Retrofit projects and new lines requiring rapid deployment. Feature: Pre-lubricated seals and robust construction support longer service intervals. Business impact: Minimizes unscheduled downtime and maintenance labor. Application: Dusty or splash-prone environments in manufacturing or automotive sectors. Feature: Clear documentation and installation guidance lowers training needs. Business impact: Shifts maintenance from reactive to proactive, improving uptime. Application: Maintenance planning and operators’ efficiency in multi-shift operations.

Get a Quick Quote for a Norgren QA/8040/61/160

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/160?

Enquire Now

FAQs

Mounting requires aligning the cylinder with the machine frame using the standard pattern and clevis or flange options. Use the provided CAD data to confirm hole spacing, then tighten mounting hardware to specification to avoid skew and uneven wear. Verify proper piston alignment before cycling at full speed to prevent binding.

This model features a 40 mm bore and a 160 mm stroke. It is designed for repeatable, precise linear motion in compact spaces. The roller-block style reduces friction and distributes load evenly, enhancing life-cycle performance in high-cycle automation tasks.

Ideal for packaging lines, pick-and-place stations, transfer conveyors, and machine-tool transfers where compact pneumatic cylinders must deliver accurate, repeatable motion. Automotive, electronics, and general manufacturing environments benefit from the robust guidance and long service intervals offered by this design.

Many Norgren automation components carry CE safety compliance and IP-rated housings for challenging environments. SIL-ready configurations are available or considered in safety-integrated systems to support functional safety requirements. Always confirm the specific unit variant and regional certifications for your installation.

The unit uses pre-lubricated seals and a robust roller-bearing guide, reducing wear and extending service intervals. This lowers maintenance labor and unscheduled downtime, improving overall equipment effectiveness (OEE) and delivering faster payback in high-cycle automation environments.