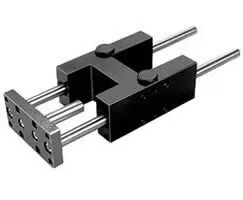

Norgren QA/8040/61/200 Guide block roller bearing style 61, 40 mm bore - 200 mm stroke

Part Number: QA/8040/61/200

Quick Summary

Norgren QA/8040/61/200 guide block roller bearing is designed to deliver precise linear motion in automated pneumatic systems. Engineers often struggle with misalignment, stick-slip, and wear during long strokes in tight-tolerance setups. When selecting motion components, consider CE certification, IP ratings, and SIL safety standards to ensure compliance and durable operation across harsh environments. In addition to robustness, this model supports straightforward installation and global support, helping procurement and maintenance teams reduce downtime and maintenance costs, while delivering repeatable performance on high-cycle lines. The combination of compact 40 mm bore with a 200 mm stroke provides a scalable solution for packaging, pick-and-place, and fixture applications.

Product Information

Cylinder diameter

40 mm

Brand

IMI Norgren

Feature: The 40 mm bore cylinder diameter provides a compact, precise actuation with consistent force. Business impact: improved repeatability reduces scrap and rework, boosting line throughput. Application: ideal for compact pneumatic cylinder installations in packaging, electronics assembly, and automotive fixtures. Feature: The 200 mm stroke extends travel, enabling longer reach from a single actuator. Business impact: reduces the number of components in the line and lowers total cost of ownership by minimizing stages. Application: well-suited for end-of-arm tooling, part transfer, and fixture indexing on packaging and manufacturing lines. Feature: The guide block roller bearing style 61 delivers low friction, smooth motion and enhanced wear resistance. Business impact: supports high-cycle operation with less maintenance and longer service life. Application: ideal for high-frequency pick-and-place and precision positioning in automation lines. Feature: Robust engineering from IMI Norgren with global support provides reliable uptime and easy sourcing. Business impact: reduces downtime and procurement lead times, improving maintenance planning. Application: suitable for multinational manufacturing facilities and OEM projects needing consistent performance. Feature: Availability of CAD data and installation guides accelerates integration. Business impact: shortens engineering validation time and reduces design risk. Application: streamline retrofits and new line builds with standard mounting patterns and ready-to-use documentation. Feature: Compatibility with standard mounting patterns and common pneumatic systems simplifies installation. Business impact: easier retrofits and scalable deployment across lines. Application: packaging, automotive, and electronics assembly environments requiring dependable motion control.

Get a Quick Quote for a Norgren QA/8040/61/200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren QA/8040/61/200?

Enquire Now

FAQs

QA/8040/61/200 uses standard mounting patterns common to guide block cylinder assemblies. For a precise fit, verify the installation guides and CAD data included in the product downloads. The CAD and PDF installation guides provide mounting tolerances, fastener sizes, and alignment recommendations to ensure a clean retrofit or new build with minimal commissioning time.

The actuator features a 40 mm bore diameter and a 200 mm stroke length, delivering compact actuation with extended travel. The guide block with roller bearing design reduces friction for smooth motion, enabling higher cycle rates and repeatable positioning in automated lines. These specs support reliable performance in packaging, assembly, and tooling applications.

Yes. The roller bearing guide block minimizes friction and wear, supporting high-cycle operation with consistent repeatability. The 200 mm stroke affords longer reach from a single unit, reducing the need for supplementary actuators and simplifying line design. For best results, ensure proper alignment and consult the installation guide during integration.

Certification details should be confirmed in the vendor datasheet and installation resources. CE, IP ratings, and SIL considerations are typically important for automation components; verify the exact certifications via the CAD resources and Installation Guide linked in the downloads to ensure your specific environment meets regulatory and safety requirements.

The low-friction roller bearing design reduces wear, contributing to higher uptime and lower maintenance intervals. The extended 200 mm stroke can reduce parts count by limiting the number of stages, lowering installed cost and downtime. Access to CAD data and installation guides accelerates commissioning, enabling faster time-to-value for automation upgrades.